Future of high horsepower could be diesel, with a boost

Practicality now drives engine and power innovation in agriculture equipment, with companies finding solutions that make more sense on the farm instead of depending on electrification.

Read Also

Battery-powered tractors proliferate, but under 100 HP

There were numerous battery-operated tractors at various levels of commercialization at Agritechnica, but almost all were under 100 HP equivalent…

The near future will include cleaner diesel combustion engines, hydrogen and battery, and often a combination.

Why it matters: The power required by farm equipment will not be met by electrification alone.

There were many electric under-100 horsepower options at Agritechnica, the world’s largest agriculture machinery show in Hannover, Germany in November, but there was also certainty that the combustion engine won’t be going away anytime soon for high-horsepower needs.

“When you go over 100 horsepower, we see that that’s where combustion still stands pretty strong. For the 700 series Fendt, it will take up to 18 tonnes of batteries. So you can imagine it’s not going to be moving anywhere,” says Tommi Puomisto, marketing manager for Agco Power.

However, innovation continues as combustion engines are made more efficient, and in a glimpse into the future, have hybrid electric, hydrogen or methanol fuel cells added to the power mix to improve efficiency.

READ MORE: Battery-powered tractors proliferate but under 100 HP

Electrification boost

Like a hybrid car, where the battery engages when the engine load and fuel consumption are highest, think of a battery-power electric motor boost that helps a combine push a slug of tough crop through, or helps a tractor start a row as it works hard to get a cultivator in motion.

At Claas, the company was on the short list for the concept innovation competition with its partial electric drive for harvesters.

“The idea behind it is to increase efficiency of the machine because in the grain harvest or corn harvest, you have some situations where you have a big load or you have heavy yields in the field and the rest of the time you can use the diesel engine with a little bit less kilowatt,” said Christian Schulte, global sales and marketing manager for combines for Claas.

During regular operation of the combine, the battery can be recharged, ready for the next high-demand period.

Combines work through variable crop conditions, which have variable power demands. Take the chopper, for example. A greener crop might require 160 horsepower just to run the chopper and spread it out the back, says Schulte. A dry crop might require 70 horsepower.

Building systems that can supplement high power needs could result in the need for a more efficient smaller engine for average operations, saving fuel and reducing carbon.

Schulte emphasized that this is currently a concept and not something available in a combine next year.

The next step is to test it with customers.

The most market-ready hybrid tractor at Agritechnica was a Steyr hybrid. Steyr is an Austrian company owned by CNH, but isn’t marketed in North America. The company is pitching the tractor on the advantages that adding electric drive can make to torque and power.

Marco Otten, a business manager with CNH and Steyr, says the company took a 180 horsepower Steyr, boosted the engine to 260, but added a generator that makes 700 kilowatts of electric power.

“We have now a newly designed front axle independent suspension with an electric drive on it.”

That brings performance advantages, with the best of combustion and electric power.

What the company calls its electric continuously variable transmission (ECVT) means that the diesel engine might be running, but the electric power can bypass the CVT and power the rear wheels for short-term, low-power operations, such as backing up to an implement.

photo:

John Greig

At John Deere, there is already a power-boost tractor on the market, its E-IVT, which is an option on the John Deere 8R, 8RT and 8RX models with 410 horsepower. The transmission has a motor and generator, so when a tractor is being used, it generates electric power. That power can then be sent back into implements.

John Deere talks about a Joskin liquid manure spreader, and the power that’s sent to the spreader and provides power to the axel of the implement. This reduces the power needed from the tractor, and provides power to the ground right at the implement, which gives more traction.

There are other options under development, says Bryan Earwood, a large tractors product manager for John Deere, although he didn’t want to go into details. He says in Canada and the U.S., the E-IVT is available now on the 8R with 410 horsepower.

Combustion engines – new editions

Beyond adding new modules to engines and powertrains, tractor companies continue to evolve their combustion engines. In Europe, most of them are compatible with hydrotreated vegetable oil (HVO) fuels, along with biodiesel.

In most new engines, HVO, biodiesel and regular diesel can be used interchangeably. HVO fuels were a prominent part of most companies’ displays at Agritechnica, as they are a lower-carbon fuel that mostly comes from recycled cooking oils. It’s also expensive at this point compared to regular diesel.

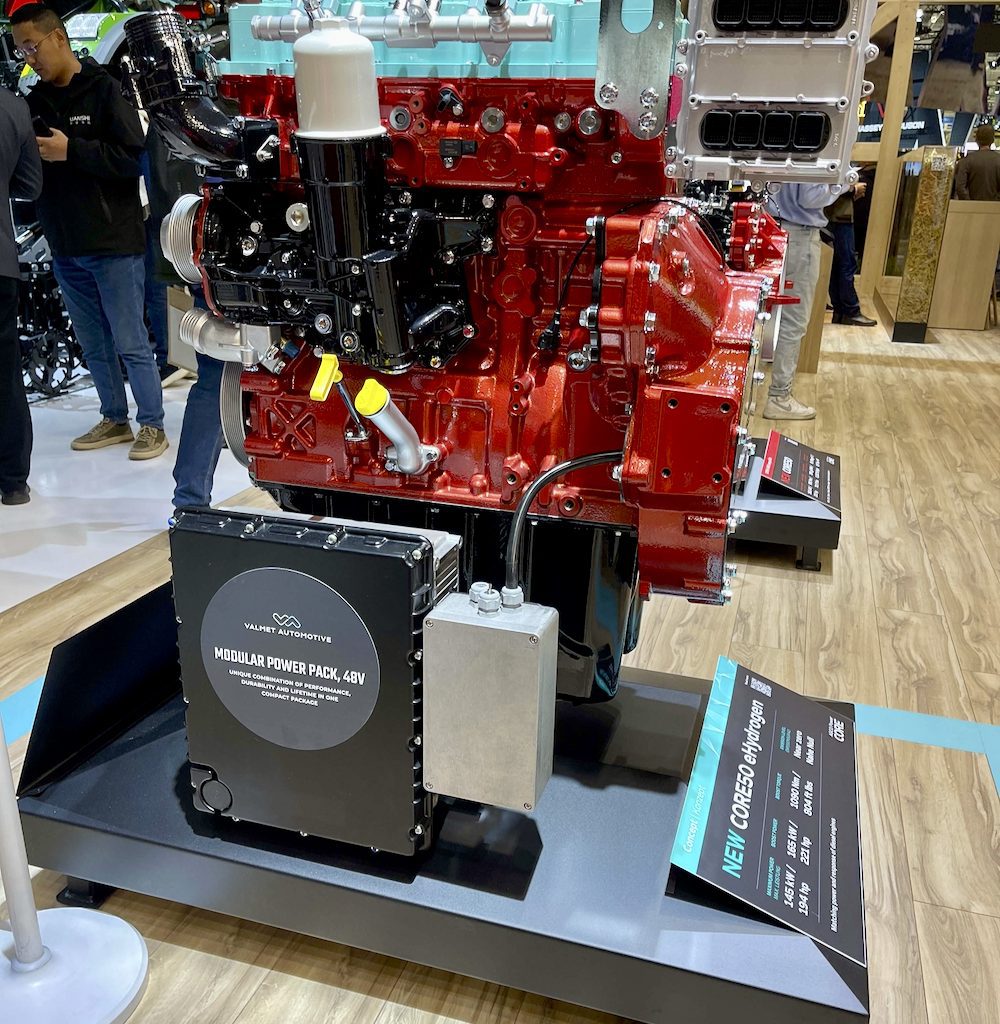

At the Agco Power display, the company featured its new fuel-efficient Power Core engine. It has created 7.5, five and 8.4 litre versions of the engines and they will form the basis of the Agco engine group into the future. The five-litre engine at Agritechnica is the one found in the 600 series Fendt.

photo:

John Greig

Beside the conventional engine was a hydrogen concept made from a retrofit of the Power Core engine.

It has been designed with the idea that, in the future, a Power Core engine could be retrofitted to hydrogen instead of buying a new engine.

“We’re showing the capabilities of the Core engine platform,” says Puomisto, of Agco Power. “What is a modern diesel engine, what does it need? One major feature that we wanted to do is that it’s capable for alternatives, like modification to use the alternative fuels like hydrogen, methanol, ethanol, biogas, straight out of the gate, even as a diesel version.”

The Core 50 e-hydrogen concept engine is running now on hydrogen and with 80 per cent of the same parts as the traditional fuel version.

Next to the hydrogen engine was an electrical boost for the hydrogen engine, as the hydrogen version is producing 194 horsepower and the traditional fuel version produces 221 horsepower.

“We’re able to bring that same response as a diesel engine and get that peak power and torque with the 48-volt battery, and an electric flywheel.”

Next to the engine display was a Fendt 700, called the Helios, with a giant white hat – hydrogen fuel cells carried on top of the cab. This is the other alternative system for hydrogen, where the fuel cells create energy, which then drives an electrical motor that runs the tractor.

Kubota also showed a similar series of engines, including hydrogen and hybrid versions, and an electric flywheel.

“At the moment, as it stands, batteries we see are limited to the lower power ranges,” says Puomisto. “It’s really important to emphasize that current modern combustion engines are as clean as it gets. They’re extremely clean compared to 10 years ago. The CO2 and the NOx (nitrous oxide) emissions are decreased by 99 per cent.”

Source: Farmtario.com