GEA’s X Control ‘lays the foundation for the integration of AI’

GEA’s new generation of control systems is taking an important step towards intelligent automation.

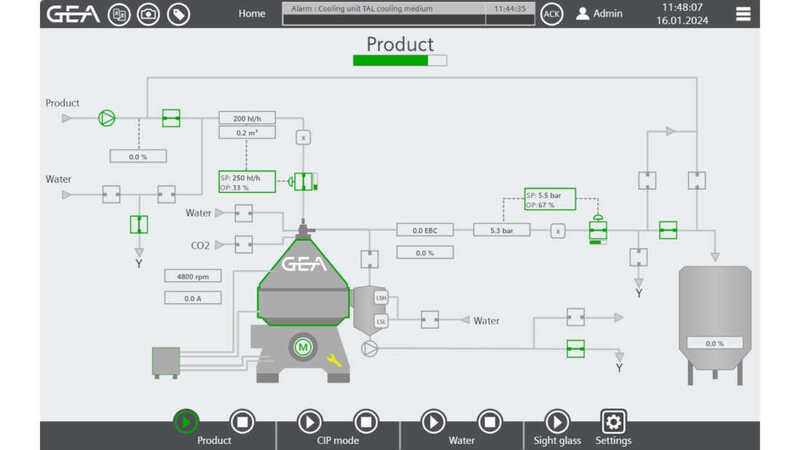

X Control brings significant improvements in terms of integration, connectivity, data processing and safety, which GEA says lays the foundation for the integration of artificial intelligence (AI). This will make data collection and analysis faster and easier in the future, including self-optimisation of an entire system.

Increased computing power will also improve integration into SCADA (Supervisory Control and Data Acquisition) systems. Cloud computing also opens up new possibilities for extended services, such as the provision of customised software functions. The new X Control will initially be introduced for selected individual machines. Availability for other GEA centrifuge types will be continuously expanded during the course of the year.

“Machine controls have evolved rapidly in recent years, noted Dieter Hille, head of automation & controls at the GEA Business Unit Separation. In the past, values were monitored and readjusted by hand or automated controllers.

“Today, we have reached a level where mass data is collected and analysed with the utmost precision. The next step is self-learning systems,” explained Hille. The new centrifuge control therefore provides the basis for the integration of AI algorithms. This means that the control system recognises patterns, draws conclusions and automatically transfers them to the control system.”

With the new control concept, GEA is increasingly relying on MTP (module type package), ie manufacturer-independent communication between components and systems. This enables users to adapt their processes even faster and more efficiently to changing market requirements by integrating all process steps quickly and easily.

The new GEA X Control also makes calculations and evaluations more complex and precise. The knowledge gained here can then be transferred back to the machine control system as instructions for action,” says Hille.

With the new GEA X Control, new customer requirements can be met faster and better in the future. High throughput and the best product quality are still priorities. “But resource conservation, such as water and energy savings, and a verifiable CO2 footprint are also important issues. And with GEA X Control, we now have even more levers at our disposal to ensure and record this in detail,” said Hille.

In order to provide customers with the fastest possible service and to ensure the availability of skilled personnel, GEA is already deploying some of its automation and service technicians across all divisions worldwide. This will be expanded in the future.

The new centrifuge control system will ensure consistent harmonisation with other divisions, such as GEA Liquid & Powder Technologies (LPT) because the HMI is based on GEA Codex, a scalable automation solution for process control levels and product control systems developed by GEA LPT, which in turn is based on ISA 101.

“Standardisation also means speed gains in engineering. Customised applications can be implemented more quickly. In this way, the customer receives hardware and software from low cost to premium for the automation solution of his choice,” explained Hille.

The new GEA X Control will initially be introduced for selected separator and decanter types for the dairy and renewables industry from the first quarter of 2024. During the year, other centrifuge types will follow, and by the end of the year, all new machines will be equipped with the new control system.

Related content

Source: foodanddrinktechnology.com