Multifunctional all-in-one sensor marks a significant advancement in accurate detection technology

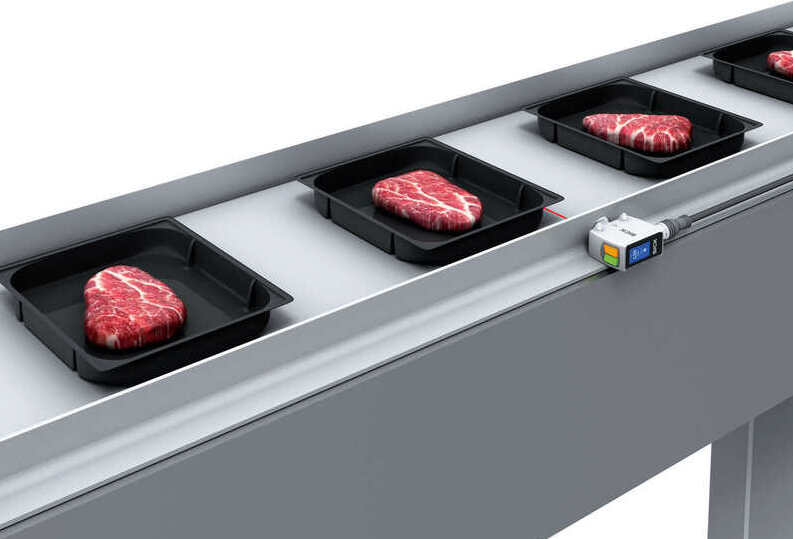

Sick W10 F&BP leading edge detection dark materials.

Sick has unveiled the world’s first photoelectric sensor with a touchscreen display, heralding the future for universal and easy-set-up sensing.

The Sick W10 is a versatile all-in-one sensor that represents a major step forward in precise detection technology, adaptable for countless food and beverage applications.

The Sick W10 photoelectric sensor’s swipe-up touchscreen technology and simple icons enable intuitive set-up and teach-in. The W10’s settings are pre-configured for rapid installation with common sensor functions, such as background or foreground suppression, available to select from a single device.

“For the first time, it’s exciting to operate a sensor that feels as natural to use as a mobile phone,” explains David Hannaby Sick’s UK market product manager for presence detection. “The touchscreen display is revolutionary. Just swipe up, select and configure. The W10 guides you effortlessly through the operating modes needed for any installation from the very big to the very small.

“With just four product variants, choosing the sensor you need for your application has never been more straightforward. The W10 turns the headache of having to select and stock perhaps hundreds of different spares into a single part number.”

The Sick W10 is a photoelectric proximity sensor that uses intelligent onboard algorithms developed from the experience of common industry applications to achieve high repeatability across the board.

With an IP69K-rated stainless steel housing and eye-safe Class One visible red laser, the Sick W10 adapts effortlessly to widespread uses in factory and logistics automation with built-in modes for standard, high-speed or precision operation. The robust Sick W10 is just as resilient to harsh washdown environments as it is on fast-moving production lines.

The Sick W10 therefore masters everyday presence and leading-edge detection duties in food and beverage applications, even with highly-reflective, dark or uneven surfaces. For example, it is ideal for detecting the level of a hopper, or for detection of the gaps between products on a conveyor eg to trigger a wrapping machine reliably.

The W10 has a secure screen locking function and access restrictions can be set up to prevent unwanted changes to the sensor settings. The single value teach-in enables rapid configuration at a defined distance, while the two-value teach-in enables objects of different heights to be detected without increasing the risk of errors. A manual mode further extends the options for maximum flexibility.

The Sick W10 incorporates IO-Link connectivity so that sensor data can be shared with Industry 4.0 IoT systems, ideal for machine diagnostics and troubleshooting, as well as for edge configurations. IO-link also provides the option of remote set-up and easy device replacement.

The Sick W10 uses the precise laser triangulation detection principle. Accurate and reliable operation is assured by the focused beam that produces a small light spot and a precise evaluation receiver. The short-range version has a working distance between 20 mm and 400 mm and the long-range version offers ranges from 20 mm to 700 mm. With a response time of 1.5 ms in speed mode, reliable switching is assured at high speeds.

Both the short-range and long-range versions of the Sick W10 are available with two mounting options: either a 1-inch hole, or an M18 thread on the front with a 1-inch hole at the side for hybrid installations. The W10 features a standard male M12 4-pin connector and both push-pull and PNP/NPN switching outputs are also available.

Related content

Source: foodanddrinktechnology.com