Beneo recovers energy from waste water to drive sustainable production

Beneo, a leading manufacturer of functional ingredients for food, feed and pharma, is continuing its commitment towards more sustainable production processes by installing new equipment at its rice ingredients plant in Wijgmaal, Belgium.

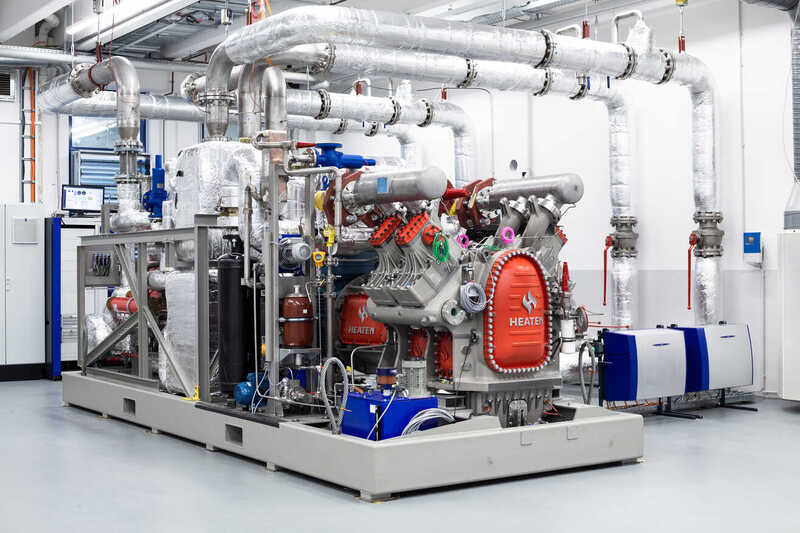

Thanks to a large-scale industrial heat pump supplied by Heaten, a specialist in industrial heat pump solutions, the company will be able to recover energy from waste water to reduce its CO2 emissions.

The rice ingredients produced at Beneo’s Wijgmaal site are used by food manufacturers worldwide to make pudding creamier, improve the dough consistency of a pizza crust or refine the viscosity of soups in a more convenient way. Manufacturing specialty rice ingredients involves both a wet extraction operation and a drying process, which requires very high temperatures. Currently, the energy for the drying process is derived from natural gas.

By investing into an industrial heat pump that recovers energy from waste water that would have been usually lost, Beneo continues to improve its sustainable energy management. Thanks to state-of-the-art technology used by the heat pump, the energy from the waste water is increased to a level that is high enough to contribute to the drying process of rice starch or rice protein. In this way, the new installation will help to significantly reduce the company’s natural gas consumption, and therefore CO2 emissions.

Beneo has been collaborating with the company Heaten as an experienced partner in industrial heat pumps to improve the sustainability of its overall production process.

“Installing the heat pump represents an important sustainability milestone for us at Beneo as it will help us to reduce CO2 emissions which is key to mitigating our overall impact on the planet. We’ve spent several months installing heat exchangers and additional piping at our Wijgmaal factory, with the heat pump expected to be operational in June 2024,” explained Roland Vanhoegaerden, operations managing director, specialty rice ingredients at Beneo.

The heat pump is the latest in a series of ambitious examples of more sustainable energy management at Beneo energy consumption inside the plant has already been made as efficient as possible through the installation of frequency converters and Beneo buys 100% green electricity from its supplier. The company has also significantly reduced carbon emissions generated from transport, after halving its inland European freight movement from road to river.

“The heat pump is our next but not our final step. It is the continuation of an integrated approach across our value chain that Beneo will undertake for the years to come,” concluded Vanhoegaerden.

Related content

Source: foodanddrinktechnology.com