Südpack and Leibinger test suitability of CIJ inks for printing on recyclable films

Südpack and Leibinger have joined forces to meet the growing demand for sustainable packaging.

The first joint project is testing the suitability of CIJ inks for printing on recyclable films for packaging food that is sterilised following the packaging process.

The tested system combination of packaging and printing solution saves food manufacturers time and ensures investment security, the two companies said.

With packaging films expected to be resource-saving and recyclable to support a circular economy, the EU Packaging Regulation requires all packaging on the EU market to be recyclable by 2030.

Composite materials are being increasingly replaced by monomaterials. If these monomaterials are not equipped with a barrier function that prevents ink components from migrating to food, they may only be printed with harmless ink. This raises the requirements for the production, coding and marking of packaging films.

As the packaging market is experiencing very fundamental changes, Südpack is continuously expanding its portfolio of recyclable films.The company is developing mono-materials that are very much on par with previous composite materials – both in terms of convenience and protection.

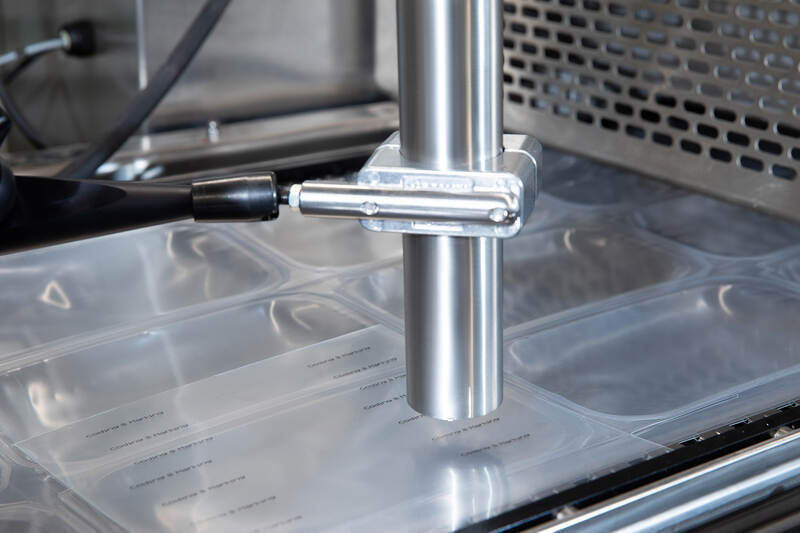

For printing and coding this type of food packaging, Leibinger offers industrial inkjet printers and develops special continuous inkjet (CIJ) inks together with SIS Ink Solution, a Leibinger Group company.

Südpack and Leibinger are testing whether continuous inkjet inks are suitable for printing on and subsequently sterilising recyclable food packaging.

Specialists from both companies investigated this very question at Südpack’s technical centre. The team printed the single-material solutions based on PE and PP with advanced CIJ ink.

During the subsequent steam sterilisation, the printed films were heated at 121°C for 30 minutes. Assessment of the print samples before and after sterilisation showed that the print was still perfectly legible.

The inks used are suitable for printing on food contact materials. This means that they only contain raw materials that are approved in compliance with the German Printing Inks Ordinance and the Swiss Commodities Ordinance.

“The sterilisation resistance of ink is always a major challenge. I am delighted that we have succeeded in developing a food-approved CIJ ink that is this effective when printing on monomaterials,” explains Dr Thomas Paul, ink expert and managing director at SIS Ink Solution, a Leibinger Group company.

Related content

Source: foodanddrinktechnology.com