Label errors dominate 2024 US food recalls, costing industry $1.92 billion

Analysis of FDA data by global labelling and supply chain solutions leader Loftware has revealed that label errors led to nearly half of all US food recalls in 2024.

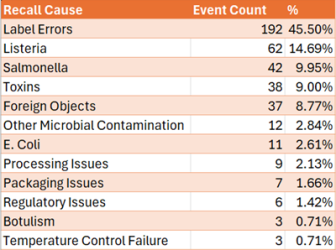

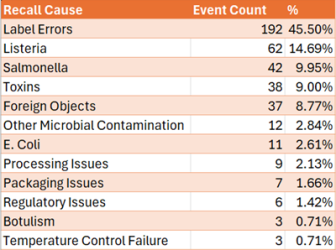

Analysis of FDA data by Loftware, a global leader in labelling and supply chain solutions, has revealed that label errors were the leading cause of food recalls in 2024, accounting for 45.5 percent (192) of the 422 recall events recorded in the FDA Enforcement Report Database.

This widespread issue cost the food industry an estimated $1.92 billion in direct recall expenses, based on the average estimated cost of $10 million per recall event, as calculated by a study from the Grocery Manufacturers Association (GMA) and the Food Marketing Institute. This figure reflects the retrieval and disposal of recalled products, not accounting for additional costs such as lawsuits, reputational damage, regulatory fines and lost sales.

Analysis of FDA Enforcement Report Database by Loftware from 1 January 2024 to 31 December 2024.

In total, 1,478 products were affected by recalls in 2024. Label-related recalls were nearly three times more common than the second most frequent cause, listeria contamination, which accounted for 14.69 percent of events. The most alarming finding was that 83.85 percent of label errors stemmed from undeclared allergens, a serious health hazard linked to at least one fatality last year.

Despite the financial and human costs, label errors often fly under the radar compared to microbial contamination cases like listeria, salmonella, and E. coli, which typically dominate headlines. Yet the frequency of label-related recalls and their associated costs demonstrate the critical need for improved labelling practices across the industry.

Importance of adopting advanced technology

Jim Bureau, CEO of Loftware, underscored the importance of adopting advanced technology to mitigate these risks. “Investment in getting labelling right delivers dividends for businesses, allowing them to avoid expensive recalls and damage to their reputation, improving the bottom line,” said Bureau.

He warned that many businesses still rely on manual labelling processes, which are prone to errors. “Software is readily available to improve the accuracy of labelling, allowing for tighter integration of enterprise resource planning systems throughout the supply chain and establishing a single source of truth for label data,” he added.

Bureau also noted that robust labelling solutions contribute to supply chain resilience, particularly in a world increasingly disrupted by geopolitical tensions, natural disasters and other crises.

As the food industry grapples with growing regulatory scrutiny and consumer expectations, addressing labelling errors could not only save lives but also avert significant financial losses.

Source: newfoodmagazine.com