Guelph researcher looking to create bioplastics from canola meal and pulse flour

Glacier FarmMedia – Renewable and eco-friendly alternatives to single-use plastics play a major role in extending the life of landfills and reducing the burden of plastic waste on the environment.

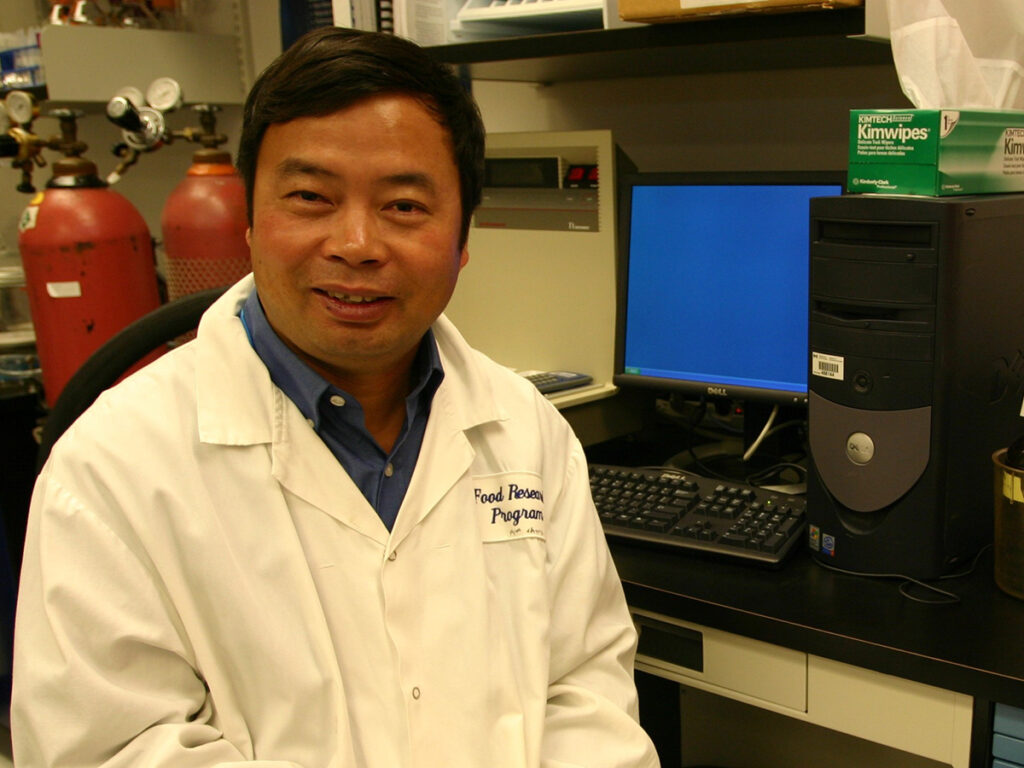

Agriculture Canada research scientist Qiang Liu and his research team at the University of Guelph are trying to find new ways to create plastic alternatives by studying how to produce biodegradable plastics using agricultural waste such as canola meal and pulse flour.

Canola meal is what’s left after the canola is extracted, while pulse flour is what’s left after pulse protein is extracted.

Read Also

Strong year predicted for Canadian dairy products, meat processors expect squeeze

It’s projected to be a strong year for dairy product makers, while meat product manufacturers’ margins may be squeezed as rising prices fail to offset higher input costs, Farm Credit Canada (FCC) said in its new Food and Beverage Report.

“Both materials are considered byproducts of the canola industry and the pulse industry,” Liu said.

“Basically, we’re trying to use those byproducts as material to develop a starch-based bioplastic and protein-based bioplastic.”

Canola meal is often used in animal feed. However, the application of canola feed is limited, so a lot of canola meal is left over each year that is simply dumped in the ground. Work to find markets for that material is ongoing, including University of Manitoba work hoping to use canola meal for biodegradable food packaging. As well, there are hopes that it will be the next big source of aquaculture feed.

Pulse four, meanwhile, is also getting a hard look as a food ingredient, among other uses.

“In the last couple of years, the pulse industry has faced a lot of challenges. Pulse protein is very hot and very popular in Costco and in retail stores. You can find those protein products because consumers like the plant-based protein. When pulse proteins are extracted from pulse flour — pea, lentil or chickpea — the leftover is starch. Pulse starch is not widely used in the food industry and other industries,” Liu said.

The attempt to create bioplastics from pulse flour and canola meal began in 2024 and is funded by Agriculture Canada.

“We have about two and a half years to go to allow us to develop those technologies to make those types of canola protein-based and pulse starch-based plastic packaging,” he said.

The research team has received pulse starch and canola meal and has started working with it in the lab.

The process takes time, and the researchers need enough material to characterize the structure, chemical composition, functional properties and composition of each substance, said Liu.

The researchers will then experiment with different chemistries and different ingredients.

Processing needs to be done when polymers can be made into different shapes, said Liu.

“At the current stage we are at, we are gathering the components and developing those functional starch-based and protein-based bioplastics, namely for packaging,” he said.

“A lot of current single-use plastics are made from petroleum-based chemicals. We hope that by using technologies, we can replace single-use non-biodegradable plastics. That is our purpose, our long-term goal,” he said.

Liu said the main priority of the research team is to develop packaging for food.

“Food packaging is a big factor in the food industry. Our bioplastic product is trying to target food, which includes fresh food including meat and other products that are wrapped,” he said.

Petroleum-based plastics do not break down easily, while bioplastics will degrade quickly.

The demand for biodegradable bioplastics is very high and grows 10 to 20 per cent every year, said Liu.

“Throughout our work, we hope we can develop a kind of bioplastic form that will benefit the environment from using a waste product,” he said.

“I think for the research work, what we also want to do is try to develop some kind of functional packaging material, which is antimicrobial, antiviral, plant polymer-based plastic,” he said.

Food waste is a major issue, and it sometimes happens because of improper packaging. Current packing material is not antimicrobial or antiviral.

“So therefore, the micro-organisms grow very easily. With all our research work, we try to develop this bioplastic, not only to be biodegradable and compostable, but to also have the function of antiviral and antimicrobial properties to extend the packaged food’s life. That is another research objective that we want to achieve with this project.”

Source: producer.com