Anuga FoodTec 2024: Coperion presents intelligent solutions for premium plant-based alternatives

At this year’s Anuga FoodTec (March 19-22, 2024, Cologne/Germany), Coperion’s Food, Health and Nutrition Division will be showcasing food processing solutions at booth B-011 in hall 10.1.

Coperion will present the newly developed and patent-pending cooling die MEGAtex S7 for the production of plant-based products as well as the new full access system for rotary valves in linear version that simplifies access and cleaning. With its P100 Batch Weigh Receiver and the high-accuracy KT20 twin screw feeder, Coperion K-Tron will present a proven solution for the precise feeding of ingredients into the production process.

The comprehensive processing solutions offered by the Coperion Food, Health and Nutrition Division comprise products from 13 leading brands, including ingredient automation, mixing, feeding, conveying and extrusion as well as portioning and depositing technologies. Coperion is now able to deliver high-quality products as well as complete systems and plants featuring a combination of products from different brands within the division.

Customers benefit from one single contact for the entire plant instead of handling many suppliers simultaneously. At Anuga FoodTec, visitors can ask experts from Coperion, Coperion K-Tron, Baker Perkins, Shick Esteve and Gabler Engineering, among others, who can provide information on food extrusion, automated processes and the production of confectionery.

For the first time, the new MEGAtex S7 cooling die for manufacturing plant-based high moisture meat analogue (HMMA) meat substitutes will be presented at Anuga FoodTec. Mounted at the discharge of the ZSK Food Extruder, this texturising unit gives the plant protein mass a dense, fibrous structure that closely resembles animal flesh.

The MEGAtex S7 cooling die allows for variable width and strength as well as various textures for meat substitutes. Moreover, Coperion has equipped the MEGAtex cooling die with features that simplify handling and make both recipe and configuration changes possible with just a few quick adjustments.

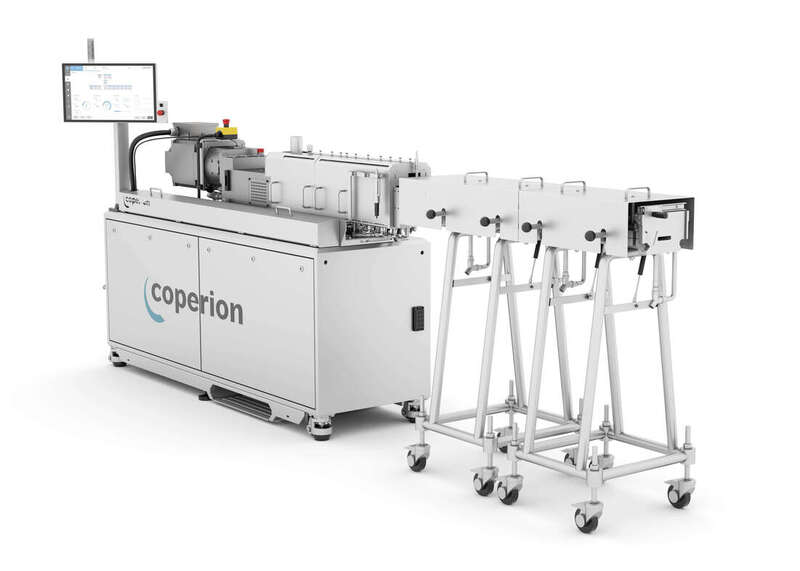

Visitors can also learn about the technologies and process expertise for manufacturing plant-based meat substitutes via the extrusion process. Coperion’s ZSK Food Extruder in Hybrid Design provides one solution for manufacturing various TVP and HMMA-based meat substitutes on a single machine. Together with high-accuracy Coperion K-Tron feeders and efficient bulk material handling solutions, Coperion offers not only the ideal technical foundation for the production process but also supports companies in developing new recipes using various proteins.

At Anuga FoodTec, Coperion will be presenting the new FXL extraction system for rotary valves in a linear version for easy extraction of the rotor from the housing, creating simplified, linear access to the valve’s interior. The new FXL extraction device not only allows for safe and simple handling but also offers high reliability. This system is especially suited for larger rotary valves and is ideal wherever strict hygienic requirements are in force and the rotary valves must be cleaned often.

A complete Coperion K-Tron batch weighing system featuring a P100 batch weigh receiver combined with a KT20 loss-in-weight twin screw feeder, mounted on a wheeled cart with a collection hopper will also be on display. The batch weigh receiver combines a vacuum receiver with a reliable weighing system.

The resulting combination allows ingredients to be conveyed and weighed so that accurate batching of ingredients can take place on either a cumulative or sequential basis. Coperion K-Tron offers batch weigh receivers in various sizes, from 30 to 1000 litres. The KT20 loss-in-weight twin screw feeder is ideal for accurately adding smaller amounts of additives to the batch. Twin screw feeders can handle difficult materials such as pigments, sticky, bridging or flooding powders.

Related content

Source: foodanddrinktechnology.com