Anuga FoodTec 2024: GEA introduces real-time monitoring

GEA is launching a new cloud-based web application for food processing and packaging lines at the Anuga FoodTec trade show, taking place in Cologne, Germany, from March 19 to 22, 2024.

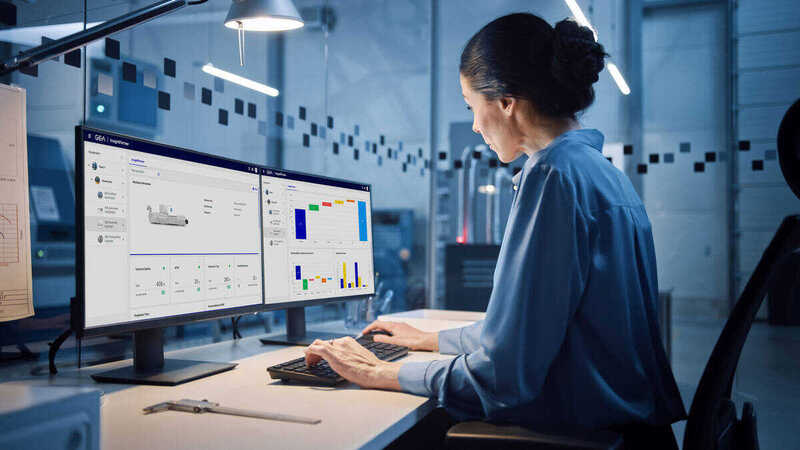

GEA InsightPartner for the food processing industry is the latest addition to its digital product family and uses machine data to provide flexible responses to production challenges.

GEA InsightPartner is designed to support all food processing and packaging plants in achieving key production goals: maximise machine availability, minimise downtime, prevent unplanned shutdowns, and manage resources efficiently. This service enhances efficiency and productivity, reduces costs, and lowers the total cost of ownership for plant equipment. By providing immediate access to historic and real-time equipment data, InsightPartner enables better production management through advanced analytics and insights from continuous monitoring. It helps identify performance improvements and extend asset longevity.

Digital innovations are transforming the food industry, enabling it to increase production while reducing energy consumption and waste. GEA supports customers with its high-performance systems, advanced sensor technologies, cloud connectivity and sophisticated analytics to help them produce more efficiently and achieve their ambitious sustainability goals.

Key features of GEA InsightPartner at a glance:

- Data-driven decision-making: facilitates optimal machine utilisation through immediate, 24/7 access to live information.

- Maintenance and troubleshooting support: aids in maintenance planning and execution, minimizing downtime and allowing for quick fault identification and resolution.

- Tracking relevant KPIs: maintains an optimal production level through collected data.

- User-friendly data access and real-time monitoring

The web application offers a user-friendly interface, allowing technical and operations managers to access historic and real time machine data. This capability ensures that performance can be tracked against key performance indicators (KPIs), promoting an optimization of productivity. The system also alerts to maintenance needs and uses trend analysis to prevent potential downtime.

InsightPartner is designed to simplify the troubleshooting process, dramatically reducing the time it takes to diagnose and resolve problems. This improvement directly contributes to enhanced maintenance efficiency and reduced production downtime. Its comprehensive monitoring dashboards provide a detailed view of equipment operation, helping users pre-emptively tackle potential issues.

GEA’s suite of digital solutions, including InsightPartner, RemotePartner, and the GEA Cloud, represents a holistic approach to supporting equipment throughout its lifecycle. These offerings prioritise security and transparency, ensuring that data is securely stored and analysed.

InsightPartner is available for a wide range of new GEA food processing and packaging machines and can be retrofitted to existing equipment. It is part of GEA’s Service Agreements program, which combines various service products for added value. The “Starter Package” for new machines integrates InsightPartner as a foundational element, providing customers with advanced analytics, improved KPI transparency, and proactive maintenance recommendations.

Related content

Source: foodanddrinktechnology.com