Danish Technological Institute strikes a breakthrough with monoplastic packaging

A number of food industry players have collaborated on a project to develop technology that can make flexible plastic packaging recyclable.

Over the past three-and-a-half years the companies, with support from Innovation Fund Denmark, have generated encouraging results to stop multi-laminate plastic packaging from food being incinerated.

The packaging is composed of several materials that cannot be separated and recycled.

About 50 per cent of the plastic in household waste is flexible films from, for example, food packaging. Of this, half is multi-laminate film, ie plastic composed of different types of plastic, and it is very difficult to recycle this plastic for the same purpose.

The Circular Mono Plastic Packaging project was representatives of the entire value chain within food packaging represented.

Søren Rahbek Østergaard, senior specialist at the Danish Technological Institute, noted that the project has worked to develop a packaging solution using monofilm, which consists of only one type of plastic and is easier to recycle.

“As part of Arla’s sustainability strategy, we would like to develop more recyclable packaging, but it’s not easy. On the one hand, packaging must protect against food waste that has a negative impact on the climate. On the other hand, we want our packaging to be recyclable,” says Lise Berg Kildemark, director of sustainable packaging at Arla Foods and project manager in the project.

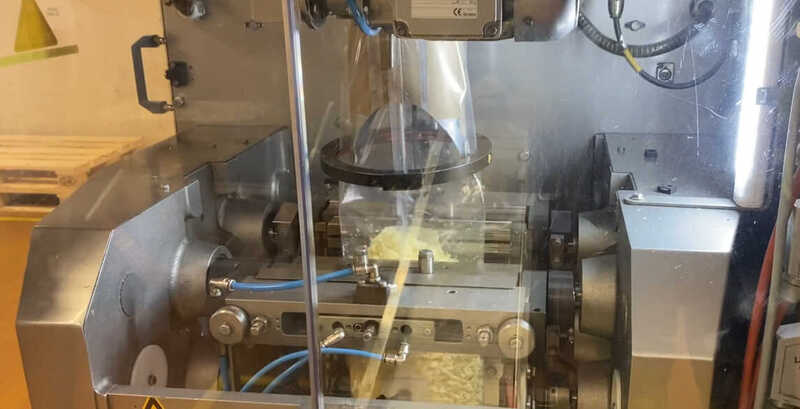

The project has developed a new monoplastic solution for packaging cheese, bread and powder.

The solution is intended to be implemented on the ordinary printing lines, where the packaging film will be decorated, and during the project it has been tested on a number of food products.

Here it has been possible to demonstrate a price saving of up to half of current costs and a CO2 saving of even more if compared to existing packaging.

If implemented, the monoplastic solution will be able to reduce the Danish burning of plastic. At the same time, it will be a competitive advantage for Danish companies, which can thus provide a solution to the recycling requirements that food producers for the European market will soon be met with.

In developing a new monoplastic solution, new technology has addressed challenges, such as food safety, welding and barrier properties as well as ensuring that the solution is circular.

New technology, for example, an insert has been developed for the printing line that can plasmacoat the packaging film – a so-called PET film (polyethylene terephthalate) – so that it achieves the necessary density to protect food. This is done at normal atmospheric pressure and with equipment already used in printing.

It has been demonstrated that the PET film can be welded on ordinary packaging lines by applying a thin welding layer precisely to the places where the film is to be welded, so that it does not exceed circularity.

It has been demonstrated that it is possible to clean the used packaging film and blow new thin film – so-called rPET – from recycled PET film. The technologies for this are still at the research stage, but the potential indicates there are good results to build on.

The ‘Circular Mono Plastic Packaging’ project officially ended at the end of 2023.

The project ‘Circular Mono Plastic Packaging’ is supported by Innovation Fund Denmark and developed under Grand Solutions.

In addition to the Danish Technological Institute and Arla Foods, the partners are the Technical University of Denmark (DTU), Nilpeter, Resino Inks, Trepko, Vetaphone, Boeras, Salling Group and the Danish Waste Association.

Related content

Source: foodanddrinktechnology.com