How the FDA traced the WanaBana lead outbreak to a single food processor

Last fall, dozens of children all over the country began experiencing symptoms of headaches, nausea, anemia and fatigue. Parents were appalled to find out that the applesauce pouches their children had been eating every day were giving them lead poisoning.

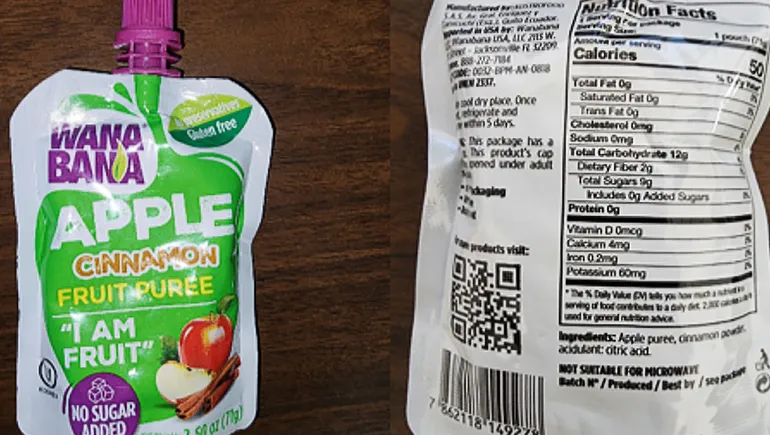

On Oct. 31, popular applesauce pouch maker WanaBana USA voluntarily recalled all of its apple cinnamon fruit purée products due to reports of elevated lead levels in certain units.

The recalled pouches eventually included three brands — WanaBana, Schnucks and Weis — all produced by food manufacturer Austrofoods. The products have been linked to 422 cases of lead poisoning across 44 states as of Feb. 9, according to the Centers for Disease Control and Prevention.

Optional Caption

In the months since the first voluntary recall, the Food and Drug Administration has traced the cause of the contamination to a factory in Ecuador that produced the pouches. On Feb. 6, the agency announced that Ecuadorian officials identified a single cinnamon processor in the country was likely the source of contamination.

The FDA’s months-long investigation touches not only on baby food manufacturing practices and supply chain issues but why the agency struggles to maintain oversight on overseas factories that produce goods bound for the U.S.

A timeline of contamination

WanaBana’s voluntary recall was first prompted by reports in October from the North Carolina Department of Health and Human Services and the North Carolina Department of Agriculture & Consumer Services, regarding four children with elevated blood lead levels. At the time of the recall, WanaBana said it was working to identify the source of the contamination.

On Nov. 9, two other products were also recalled: Schnucks applesauce pouches with cinnamon and Weis cinnamon applesauce, both of which are made by WanaBana USA.

On Nov. 16, the FDA proceeded to test a WanaBana applesauce pouch collected from a Dollar Tree store, in which they found a lead level more than 200 times greater than what the FDA says is safe for fruit purees and similar products intended for babies and young children.

The FDA then performed an onsite inspection at the Ecuador-based Austrofoods facility that manufactures WanaBana products on Dec. 5. Austrofoods was founded in 2008 and only has one location, in Pichincha, Ecuador, according to its LinkedIn.

The agency also investigated Negasmart, the third-party Ecuador-based distribution company that supplied the cinnamon to Austrofoods.

During the FDA’s testing of the recalled products and the cinnamon, the agency also found chromium in the pouches, according to a notice on Jan. 5, 2024.

Both lead and chromium can be toxic at elevated levels, especially for children, according to the Centers for Disease Control and Prevention.

Ecuadorian officials identified cinnamon processing company Carlos Aguilera as “the likely source of contamination” of the pouches on Feb. 6. Carlos Aguilera sourced its cinnamon sticks from Sri Lanka, which, according to Ecuadorian officials, were free from lead contamination before they were processed.

Carlos Aguilera is not in operation at this time, according to the Feb. 6 FDA update.

The FDA’s authority to intervene with the foreign suppliers and manufacturers involved in the contamination at this point is limited, however, because Negasmart and Carlos Aguilera did not ship their products directly to the U.S., the agency said in the update. Their products underwent further processing prior to export.

WanaBana did not respond to a request for comment.

What does this case mean for U.S. food manufacturing?

The FDA confirmed it’s exploring a theory that the cinnamon contamination occurred as a possible result of economically motivated adulteration. Such an incident occurs when someone intentionally leaves out, takes out or substitutes a valuable ingredient or part of a food, according to the agency.

“The current incident of elevated lead levels in cinnamon applesauce pouches is highly unusual,” an FDA spokesperson said to Manufacturing Dive in an email.

Because the levels of lead were well over the drafted FDA guidance and can be injurious to health, the products are considered adulterated under the Federal Food, Drug, and Cosmetic Act, the spokesperson added.

Steps in the baby food manufacturing process are highly surveilled by the FDA. Baby and toddler food manufacturers must implement controls to test for toxins such as arsenic, cadmium, lead, chromium or mercury to significantly minimize or prevent any chemical hazards from getting into products, the spokesperson said.

The FDA also created the Closer to Zero initiative in 2021, which focuses on research, regulation and consultation that can help reduce children’s exposure to these contaminants. In January 2023, the agency proposed new, lower action levels for the maximum amount of the contaminants that can be found in fruits, vegetables and other foods. The draft action levels of 10 parts per billion or less would apply to fruit puree pouches like the WanaBana products.

WanaBana cinnamon apple pouches were 200x greater than guidance allowed, FDA finds

Mean lead levels, in parts per billion, of Food and Drug Administration analysis of lead concentrations in certain food categories.

Some experts, however, don’t believe the initiative goes far enough, such as Jane Houlihan, research director at food safety advocacy group Healthy Babies Bright Futures. Houlihan noted the action level the FDA proposed for lead in baby food would reduce infants’ dietary exposure to lead by only 3% to 4%. This is because the FDA data did not include infant formula, homemade baby food ingredients and other store-bought foods in its guidance, according to the advocacy group.

“We’d like to see the FDA establish action levels that are more health protective,” Houlihan said. “They’re setting a standard that is easily achievable by industry, but that doesn’t have a big health benefit for babies, and their priorities are out of place in their actions so far under Closer to Zero.”

The Closer to Zero initiative is still in draft guidance form. The FDA hopes to issue final guidance on lead-specific action levels in baby and young children food manufacturing by December 2024.

“We’d like to see the FDA establish action levels that are more health protective. They’re setting a standard that is easily achievable by industry, but that doesn’t have a big health benefit for babies, and their priorities are out of place in their actions so far under Closer to Zero.”

Jane Houlihan

Research Director, Healthy Babies Bright Futures

Because of a current lack of regulation, Houlihan said manufacturers must only adhere to their own internal standards, leaving the door open to elevated contaminant levels.

“We’re hoping that they really ramp up the program in a meaningful way and do more that has a downstream benefit for babies,” Houlihan said. “There’s so much bureaucracy and scientific analysis involved in establishing an action level, and for the first big action level to come out of this program, the lead action level to have such a small benefit for children’s health is really disappointing.”

She hopes to see mandatory federal testing of ingredients from suppliers and finished foods.

“Most baby food companies want to sell food that’s healthy for babies. So if there is a federal guidance level in place, they have an interest in paying attention to it,” Houlihan said.

Because of the recent WanaBana investigation, the FDA expects to conduct additional testing of cinnamon and cinnamon containing foods consumed by babies and young children, the agency spokesperson said. The agency will look at samples collected domestically and at foreign facilities and consider more inspections of plants that use cinnamon in their finished products.

Both foreign and domestic manufacturers are responsible for ensuring the safety of the products that enter the U.S. market, the spokesperson added.

“FDA’s oversight of the food supply remains consistent and vigilant,” the spokesperson said. “As a result of the information obtained during this investigation, we anticipate continuing to inspect other firms and investigating to ensure that a similar incident does not happen in the future.”

Source: fooddive.com