Inverafrut has opened a new packhouse in Texas, USA. According to CEO and owner Adriana Melchor, this packhouse is filled with high-tech goodies: “For the correct processing of the received goods, a high-tech sorting machine was installed for packing in mesh bags, boxes type RPC or 40-pound cardboard with a capacity of 15 ton/hr for limes and 20 ton/hr for avocado. The classification is carried out by color and size as in any other classification machine with an accuracy of up to 98%.”

At the center Luis Ohmar and Adriana Melchor holding the scissors to cut the ribbon

Melchor states that Inverafrut aims to both increase capacity in the North American region, as well as be able to pack several new products. “With this project we increase our distribution capacity within the American and Canadian markets, as well as generate a wider portfolio of presentations that allows us to adapt to the most demanding markets with a better presentation in meshes for 1lb, 2lb and 5lb. We can not only process the Persian lime, which is our flagship product, but several other products as well, adding at least ten more items.”

A well deserved celebration for this success, Adriana with the black hat.

A well deserved celebration for this success, Adriana with the black hat.

The machine has been put together by technologies from different origins. Melchor explains there was an emphasis on making it a one of a kind multitask machine: “This imported hybrid machine has been designed with the influence of Spanish, French, Israeli and American technologies, which allows us to process different products with the same type of hardware. We use existing technologies from various developers for the best treatment of products that are most commercialized. We then integrate these technologies into a machine that is capable of processing them in an easy and gentle way, as if it were a human hand, while taking the classification theory into account and respecting the different characteristics for each product. It’s become a multitask machine and honestly unique in its kind. An interesting fact that should be highlighted is that when the machinery is fed, the human hand does not directly touch the product until it becomes a finished product and ready for distribution. To ensure the food safety of the finished goods, as a last safety point, all pallets go through a final revision process to guarantee the quality of the finished product.”

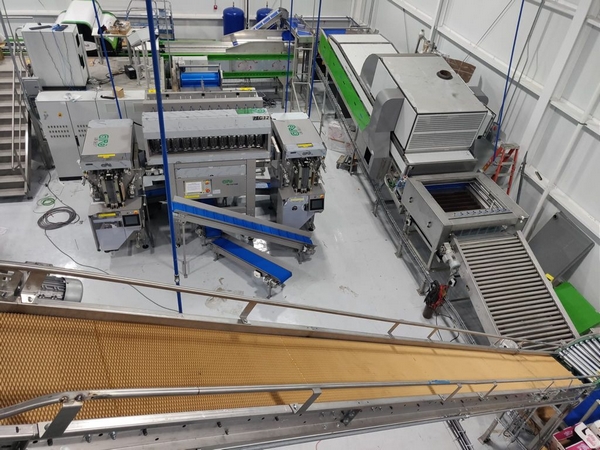

The new facilities

Naturally a packhouse doesn’t just consist of the production floor and the building will house several other staff as well: “The offices are equipped with a high-speed internal network for the constant flow of data in the daily processes in which we work. The building has a capacity of up to 15 administrative staff and the production area is designed to be able to optimize spaces and maximize the efficiency of work with up to 20 people with minimum effort. Our facilities represent the first stage of the modernization of our American branch and thinking about the development of the second stage in the not too distant future.” Melchor concludes.

The new facilities

For more information:

S. Adriana Melchor

Inverafruit USA LLC.

Tel: +1 (956) 587-2468

Email: direccion@inverafrut.com

www.inverafut.com