KPM Analytics releases an advanced, AI-powered 2D and 3D vision inspection system

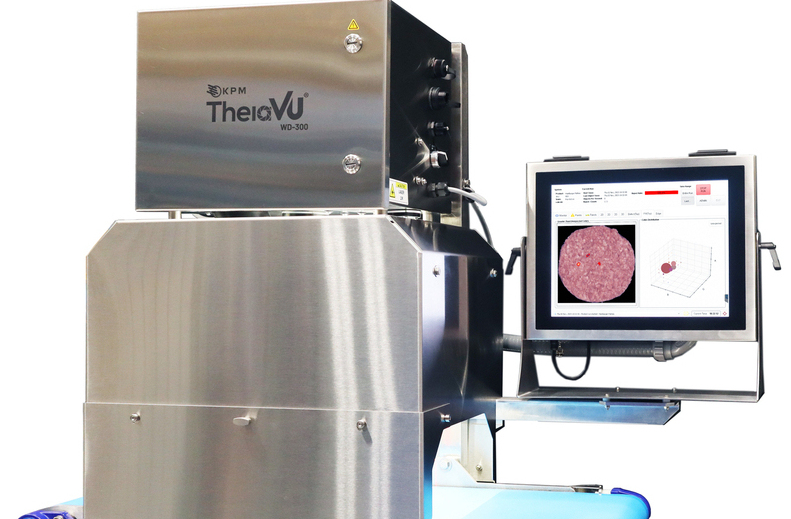

KPM Analytics has introduced the TheiaVu WD-300, the first AI-enabled at-line vision inspection system designed specifically for meat and poultry.

Recognising that meat and poultry processors face ongoing challenges with quality control, consistency, and labour shortages, the AI-powered TheiaVu WD-300 includes advanced features and capabilities from previous system generations to answer specific demands from users in the meat and poultry industry.

It eliminates the need for calipers and colour charts to save labour and avoid subjective assessment. The at-line visual inspection reduces all these manual measurements into a single pass through a conveyor for greater precision, reliability, and speed compared to other visual inspection methods, the manufacturer noted.

The TheiaVu WD-300 is optimised for a wide range of meat and poultry products, including chicken portions, beef cuts, processed meats and other further breaded products such as chicken nuggets and sandwich patties.

In addition to traditional rule-based vision techniques, the TheiaVu WD-300 vision inspection system leverages sophisticated artificial intelligence to analyse product attributes quickly and accurately. It can assess key quality indicators such as product thickness, fat distribution, and cook colour even on breaded products, as well as measure size, shape, and detect blood spots or foreign materials.

Each TheiaVu WD-300 is equipped with measuraAITM, available in measura 4 software, which provides a simple interface that allows users to take advantage of recent developments in artificial intelligence and train their own AI models based on provided templates for their unique products. The measura 4 software is also available in all TheiaVu models, including the TV-250 product line for the baking industry.

As optional add-ons, the TheiaVu WD-300 also interfaces with an integrated weighing scale or product temperature probe to complete quality assessment needs.

The new system offers rapid, objective analysis of multiple product attributes in a single pass. Customers participating in beta testing of the new system report significant increases in inspection speed, more consistent results, valuable data insights, and allows them to get the highest value for their products, .

The TheiaVu WD-300 vision inspection system offers a rapid return on investment. The TheiaVu WD-300 can be located on the production floor or in the quality lab and used to inspect every line. In this way, the TheiaVu WD-300 system provides a steppingstone for more automated in-line inspection in the future. KPM Analytics inline inspection systems, such as the KPM P-Series utilise the same software interface as the TheiaVu WD-300 for seamless measurement transfer to the production line.

Processors can dramatically increase the amount and consistency of data collected. As labour challenges persist in the industry, company managers will appreciate the opportunity to:

- Ensure compliance with customer specifications and reduce the risk of costly product rejections.

- Increase sampling rates with the speed and consistency of the AI-powered analysis.

- Realise a more representative picture of overall product quality by collecting data on more samples in less time.

- Enjoy a user-friendly setup due to the system’s AI programming. This allows new product specifications to be added in minutes rather than hours for a line change or product reformulation.

- Save time by using included AI libraries for meat and poultry products, with digitally stored data for easy retrieval.

Additionally, the system is specifically designed for the harsh environments typical of meat processing plants. Its washdown-ready housing and removable, easy-to-clean conveyor belt supply the combination of durability and hygiene required in the meat industry. The system also includes an IP69-rated touchscreen operator interface with integrated PC.

Jon Gilchrist, technical solutions director for protein vision inspection systems at KPM Analytics, said the system can increase sampling rates by tenfold or more compared to manual methods while also expanding the range of measurements taken.

“This level of data collection and speed is simply not possible with manual inspection or modified, basic camera systems while adding in objectivity and reliability that reduces waste and positively impacts profitability,” he added.

Related content

Source: foodanddrinktechnology.com