Masterpress integrates full-scale printing press for R&D

Masterpress has expanded its research and development (R&D) capabilities at its facility in Białystok, Poland, by integrating a state-of-the-art, full-scale printing press exclusively for R&D purposes.

This addition marks a pivotal step for the European provider of printed decorated packaging in its journey towards pioneering the development of sustainable, recyclable packaging solutions in the shrink sleeve and self-adhesive label industry.

“Expanding R&D capabilities is fundamental for us as it fulfils our commitment to continuously enhance our products and services,” said Jeroen de Haan, general manager of Masterpress. “The shrink sleeve and packaging industry evolves, and to progress we must use cutting-edge technologies, test and trial new products, solutions and materials faster and more effectively.”

The new printing press will serve as a versatile tool for research and development across various product groups. Offering flexibility in trying new printing techniques on a scale simulating actual production, without the need to wait for a gap in the regular production schedules, the press allows Masterpress to significantly speed-up new product development processes and time-to-market.

“The R&D press enables us to be a much more agile and effective development partner for our customers, quickly turning their creative vision into real product samples. This also improves our collaboration with our suppliers, bringing in the capability to test and trial their new inks or materials before they enter the market,” said Katarzyna Wasilewska, research and development manager at Masterpress.

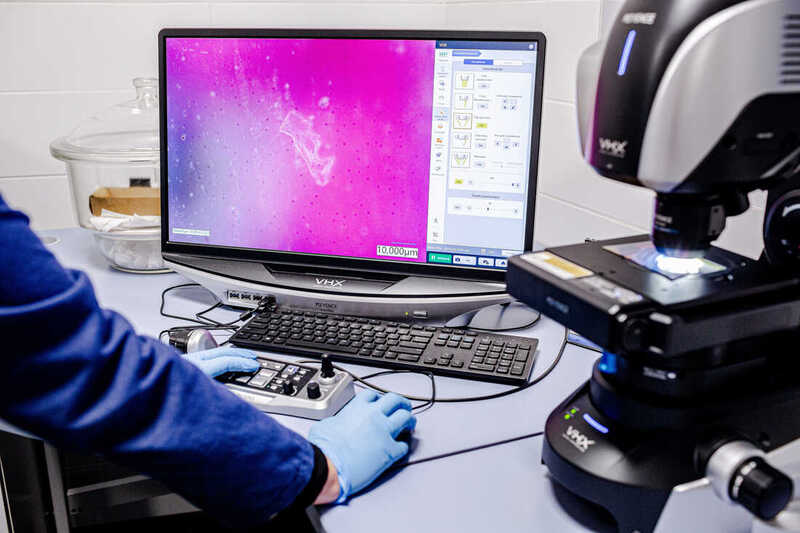

Masterpress has been consistently investing in its R&D laboratory for over a decade. Along with the new printing press, the research and development laboratory in Białystok is equipped with state-of-the art tools allowing for precise testing of substrate strength, slip and friction as well as simulate resistance of the various products to temperature, solar or shop-floor light.

“By expanding our R&D capabilities we take another step in the long-term growth strategy of Masterpress. We want to drive the market forward with sustainable development and help the label industry to be seen as a positive contributor offering “good-for-recycling” solutions.”

Masterpress’ inventive and “designed-for-recycling” packaging products have been widely recognised by the industry across Europe. The most recent accolade includes the AWA Alexander Watson Associates Sleeve Label Award in the Environmental Winner category for the TINE 300g Dairy Cup Sleeve.

Related content

Source: foodanddrinktechnology.com