Mettler-Toledo’s ProdX software upgrade empowers food manufacturers to reach new levels of QA

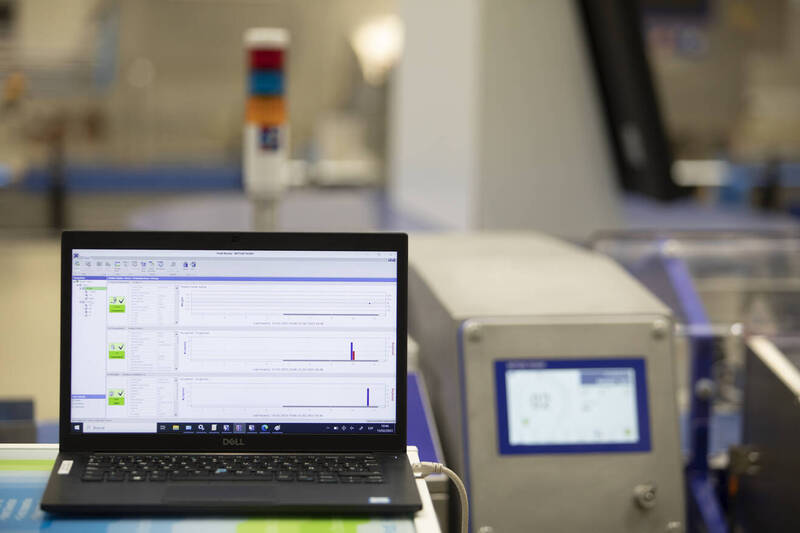

Mettler-Toledo Product Inspection’s the release of ProdX 2.7, the latest update to its data management software for product inspection.

ProdX software is designed to save manufacturers time and money by automating essential quality control processes. It monitors, reports and collates all product inspection activities in real-time, helping manufacturers support regulatory compliance and protect their brand through the safe storage of data. By analysing this data, production line improvements can be easily identified – boosting productivity and combating rising costs.

Designed with the evolving needs of food production lines in mind, ProdX 2.7 builds on the existing foundations and now offers significant advancements to improve operational efficiency, product quality and sustainability, while continuing to facilitate compliance with local and global regulations.

Mettler-Toledo Product Inspection says ProdX 2.7 represents a major leap forward in the ongoing commitment from Mettler-Toledo to optimising product inspection processes for food manufacturers. This new version delivers key improvements to reporting, user management, device integration and operational transparency – enabling manufacturers to boost efficiency, reduce costs and achieve high levels of compliance and safety across production lines.

Peter Spring, ProdX product manager at Mettler-Toledo, notes how ProdX 2.7 takes its software to the next level in terms of usability, connectivity and efficiency.

“It offers a range of new features that allow manufacturers to automate time-consuming tasks, improve the speed and accuracy of reporting and ultimately deliver a higher level of product safety and compliance. As food manufacturers face increasing demands for sustainability and efficiency, ProdX™ 2.7 provides the tools they need to meet these challenges head-on.”

Related content

Source: foodanddrinktechnology.com