Provisur Technologies future-proofs product handling

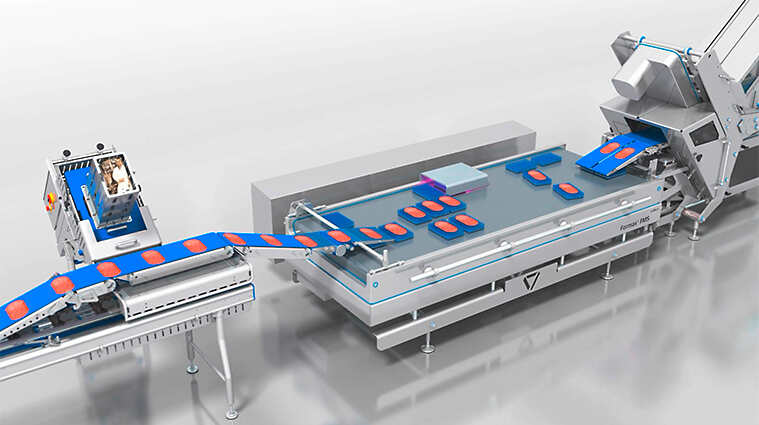

Provisur Technologies’ new Formax Free Movement System (FMS) is a compact and hygienic handling system for sliced products that offers a high level of flexibility, making it ideal to overcome the challenges of today’s ever-changing markets.

The FMS utilises free-floating movers that ride along an electromagnetic surface to enable smooth and seamless product handling. The movers on the FMS tabletop can be programmed with any type of motion profile including rotation and synchronised travel in any direction. It enables portion handling control and is ideal for complex product applications that require a high level of flexibility. It easily handles

high-volume slicing lines, adult snack pack lines, sandwich lines, twin stacks, multiple packs, and more.

Electromagnetic tiles are at the core of the machine’s ground-breaking technology, along with the transport units known as “movers”. The movers hover over flat surfaces without any physical contact and require no guiding elements such as rails or conveyor belts. They glide the portions seamlessly from slicer to packager.

Patented loading and offloading technology ensure a smooth transfer of portions from mover to downstream equipment and is designed for high-speed operation.

The electromagnetic technology of the FMS is uniquely versatile and flexible. It eliminates the need for extra components such turning stations, buffers, inliners, or overlappers. As the movers have the ability to move anywhere on the work surface, this simplifies the pickup of sliced products for transportation. Once the product moves from the slicer to the mover, the system establishes a buffer to accommodate the loading pauses necessary for reloading new products into the slicer. During these pauses, the buffer unloads to maintain a continuous product flow to the packaging machine.

The system can easily be adapted to process new applications: the ability to enter new software programs to accommodate new applications delivers future-proof operations that allow food producers to react swiftly to market changes. Existing machines already in use can also be retrofitted with the FMS.

In line with Provisur’s sustainability principles, the FMS is a simple machine that does the work of many. This simplicity leads to a small footprint, with significant space savings of up to 50% compared to traditional product handling systems which often require multiple machines. In contrast, the FMS assembles multiple assortment portions in a very small space.

As a result of the simple design, the FMS has fewer moving parts to clean and maintain, thereby substantially increasing system availability by minimising downtime. Additionally, for producers facing growing staff shortages, the streamlined processes of the FMS reduce the need for costly production and maintenance staff.

The extremely hygienic overall design eliminates the possibility of contamination as there is no human contact with the product: the sliced product is automatically transferred directly to the movers. Furthermore, the multiple transfers in other systems can disrupt sliced portions and hurt product presentation, while the smooth mover motion and gentle product transfer of the FMS protect the quality of the final product.

Related content

Source: foodanddrinktechnology.com