Regloplas offers digitalisation in process temperature control

Lockdowns and pandemic-related employee absences are making it difficult for many food producers to maintain their usual production capacity. You don’t send a machine or plant operator to work from home lightly. Production of dairy products, pasta, pastries, confectionery, food additives, even new types of foods such as plant-based meat replacements must continue, even when everything around is at a standstill.

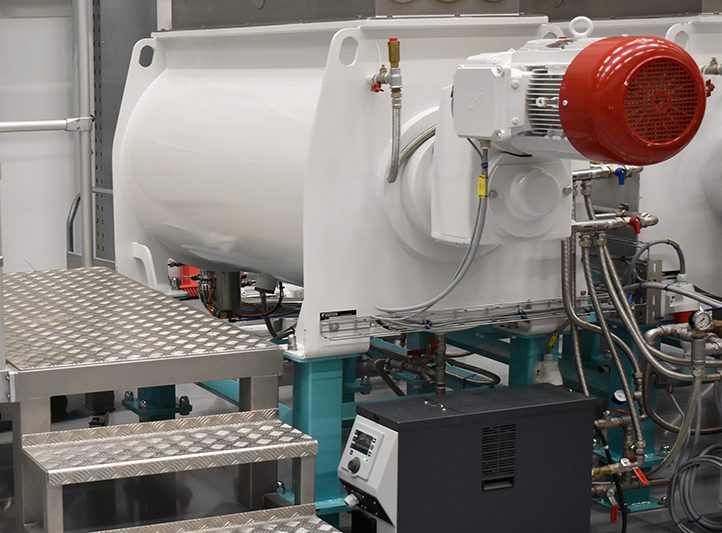

The food industry therefore made advances in digitalisation last year which would otherwise have taken many years. And this development has had a major impact on temperature control. Systems which operate for 24 hours per day must record the core parameters over the entire production process to comply with the regulations of hygiene and traceability e.g. the temperature of grinders for chocolate production, the bath or screw temperatures of extrusion plants for pasta or confectionery, temperatures in double-walled vessels (often with agitators) for tempering fluids, temperatures in pipe lines for transporting various semi-finished or finished products, and increasingly also large reactors which can be used for everything from sugar production to the production of natural flavourings for foodstuffs.

Any deviations from the standard, temperature deviations, alarms etc, must trigger the necessary remedial actions immediately, especially at those times when there is no-one standing by the system. There are also the needs for remote support by the plant manufacturers’ service technicians and the ongoing optimisation of the whole production plant.

To provide even better support to its customers during this development, Regloplas AG is offering a range of solutions for its temperature control units and cooling systems (-20°C to 350°C and 3 to 80kW heating capacity) which drive forward the digitalisation of temperature control in the food industry.

Regloplas AG’s new RT200 control system with integrated OPC UA server now offers maximum flexibility for digitalisation within the production process. The central concept of digitalisation is data exchange of all the process and machine data across the network and to higher-level IT systems such as MES, ERP and PPS.

All peripheral machines, devices and systems involved in the production process communicate with one another. This enables real-time process optimisations leading to higher productivity, reduced downtime, optimised machine capacity and improved product quality. (fig1)

The use of temperature control units from Regloplas AG’s modular toolbox offers a series of additional advantages, according to the company:

- Cost reductions compared to plant manufacturer’s own solutions (produced in small quantities) – Problem-free continued use of the temperature control unit in a new or upgraded system.

- Technical improvement and increased reliability due to the use of a temperature control unit by a manufacturer specialising in temperature control.

With less outlay on the integration of high performance and flexible temperature control solutions, is equally attractive to plant manufacturers and to processing operations. Regloplas AG is continuously developing its offers and technical expertise for these users. The company says its motivation, in addition to economic considerations, is being able to contribute to a healthier, tastier and sustainable food supply.

For more information, visit: www.regloplas.com/en.

Source: foodanddrinktechnology.com