Seven steps offered to maximize crop quality

A seven-step outline for maximizing moisture and quality control at harvest has been developed by Dave Wall of Wall Grain and Calvin Boisjoli from GrainX. The two have worked grain bin management for more than 20 years.

Harvest sooner

Tough grain is canola at 12 percent and cereals at 17 to 18 percent. Harvesting early gets the jump on harvest and also captures grade and quality. Earlier harvested cereal grain can be three pounds per bushel heavier than cereals harvested after rain or deteriorated in the field. With tough grain in the bin, the farmer now has 16 percent grain to blend with 12 percent grain. Malt barley harvested early can bring $2 more per bushel.

Safe storage time

Many producers leave grain in the field way long so it loses moisture, grade and bushel weight. Tougher grain will keep in a safe condition while fans are running selectively but not continuously. The sooner the grain is harvested, the more time is available to run fans with the right quality of air, preserving moisture and grade.

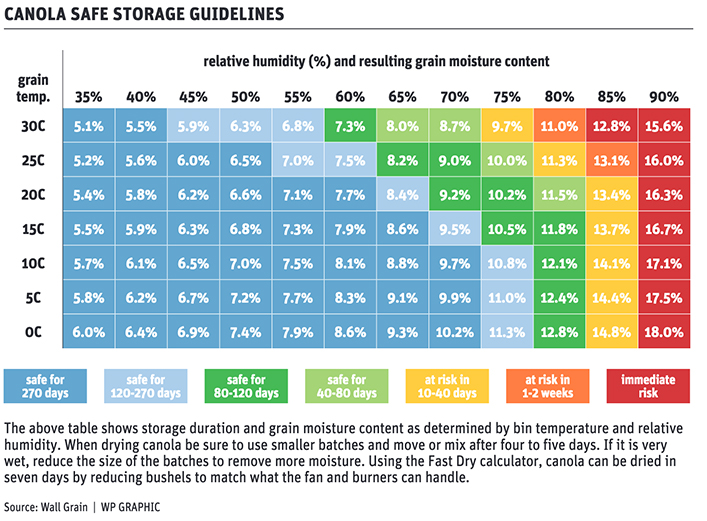

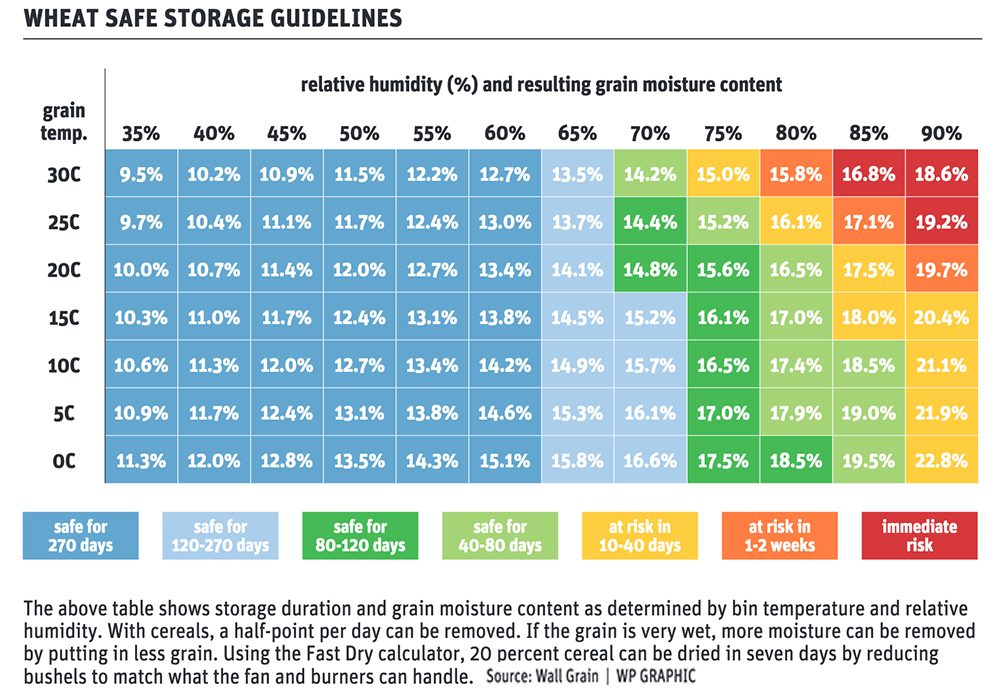

The charts show safe storage times for canola and wheat. They also show how running fan air will affect grain under specific ambient temperature and humidity conditions. For example, 11.5 percent canola is binned at 20C. This grain is in a safe storage condition for up to 80 days. As the temperature or moisture drops by running the fans in the correct conditions, the safe storage time increases.

Target run time

Any time the fan runs at less than 80 percent humidity, at any temperature, the canola is drying. Conversely, any time the fan runs at more than 80 percent humidity, moisture is added. Earlier harvesting gives better weather opportunities for warmer and drier air to target the correct fan run time. This is easier with automation that starts and stops the fans based on weather conditions and grain condition monitoring feedback. Fans should be run selectively when drying grain. Don’t over-dry or rehydrate it by running fans all the time.

Dry aeration

Most big bins have high airflow, so holding cereals at 19 percent or canola at 13 percent is no problem. Monitors allow producers to keep the combines rolling to maximize moisture from the field. Shrink occurs when hot grain from the field is cooled through dry aeration, and tonnes of bushel weight are lost. Canola binned at 10 percent at harvest and shipped at eight percent results in a loss of 600 bushels.

For every 10C temperature drop, approximately 0.5 percent in moisture is lost. This is more pronounced with temperatures near 30C. Farmers can minimize this loss by running fans at higher humidity and on cooler nights. GrainX Command fan automation can turn on fans during the correct window. By knowing the safe storage time, farmers can wait for cooler, higher humidity days to run the fans. Dry aeration is the second most economical way to dry grain without adding huge capital cost and can also be used with a grain dryer.

Blending

This is the lowest cost and lowest risk method of drying grain and capturing moisture. Tough grain harvested earlier that is not drying fast enough in the bin can be blended on the farm or “paper blended,” where the farmer makes a deal with the terminal to bring in different dry percentages of grain. Heat can also be added to some bins if there is too much wet grain. Coaching is available from GrainX Management Services on mixing dry and wet grain on the farm instead of paying penalties on delivery.

Hydration

In many areas it’s nearly impossible to take grain off at higher moistures. After all the hard work has been done to get the grain in the bin, selling it below moisture thresholds is a lost opportunity cost.

Using the safe storage charts on this page and the next, an automated system like GrainX Command will run fans when the air is wetter than the grain. This hydrates from the bottom up, adding moisture to grain in storage.

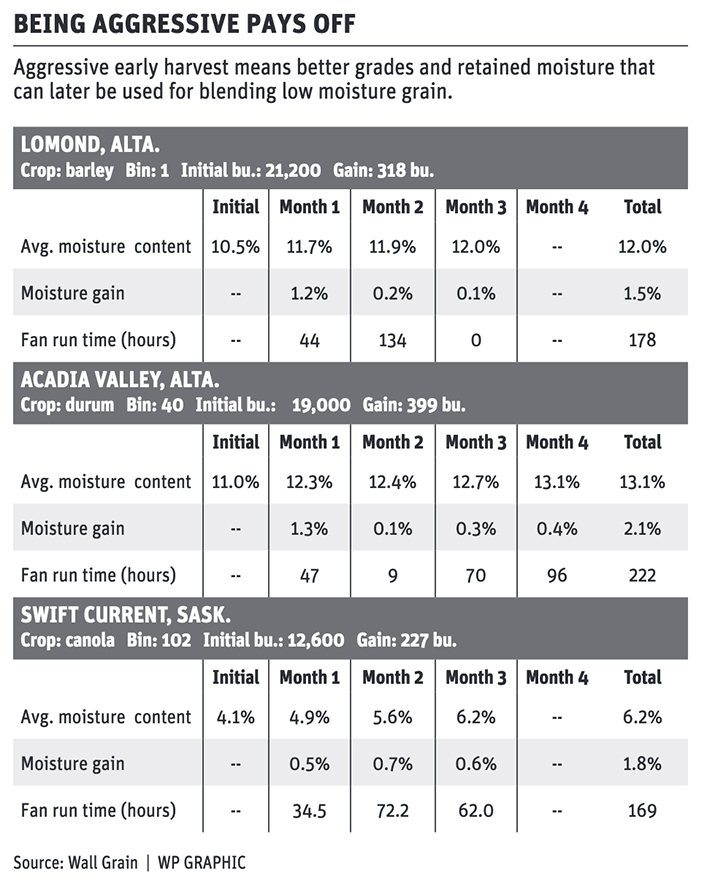

See the chart for real customer data from fall 2020 and this spring from producers who add moisture and value to their grain.

Wall says, “We hear of some producers adding water to their loads of canola. This is something we do not recommend for various reasons.”

Fan automation

GrainX Command Automated AI is a patented autonomous grain management platform that includes coaching and implementation assistance. It can be added to existing digital temperature and moisture cables and incorporated into BinSense Live infrastructure.

Many farmers are using a combination of these seven strategies, saving the cost of a grain dryer and handling system.

Source: producer.com