Tate & Lyle celebrates opening of new capacity at Slovenian plant

Tate & Lyle opening in Boleraz, Slovakia.

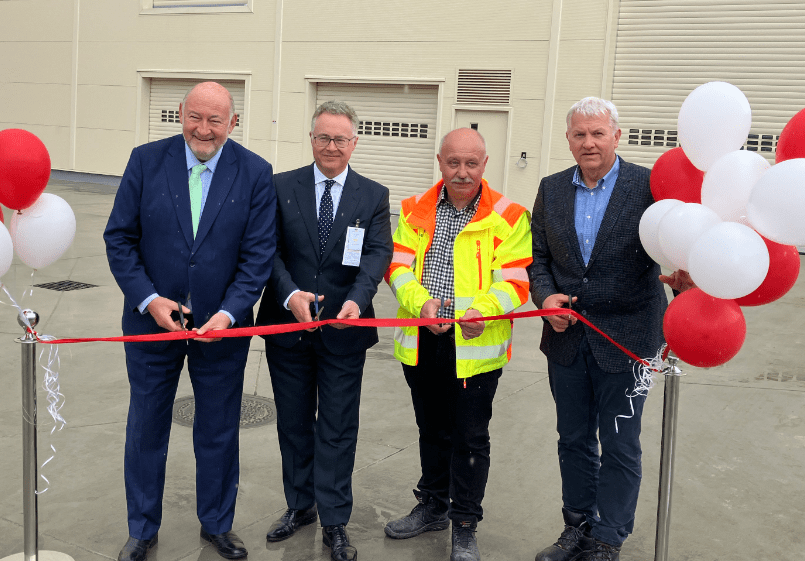

Tate & Lyle has welcomed the British Ambassador to Slovakia.

Nigel Baker, Tate & Lyle’s chair, David Hearn and other guests to celebrate the formal opening of new capacity at its facility in Boleráz, Slovakia, for its non-GMO Promitor Soluble Fibres.

The new capacity, representing a €25 million investment, is the first phase of a programme expected to significantly increase Tate & Lyle’s fibre capacity to serve both its European and global customer base. As well as providing new capacity, the project generates sustainability benefits through supply chain optimisation and improved energy efficiency.

Igor Kovačovič, Tate & Lyle’s plant manager at the Boleráz facility, said: “As a result of Tate & Lyle’s proprietary fibre production know-how, and through the use of the latest technology, this state-of-the-art facility gives us the ability to expand existing Promitor product lines and seamlessly introduce new ones in the future.”

The new capacity comes on line at a time of growing consumer demand for dietary fibres, not just as a tool for improving gut health but also supporting overall health, immunity and mental health. It also aligns with customer requirements for added fibre and improved nutrition benefits. Tate & Lyle’s proprietary research shows that over half (54%) of global consumers plan to consume more fibre. Customer demand for sugar reduction solutions continues to grow and fibre is playing an increasingly important role, as a value added, nutritious bulking ingredient.

Promitor Soluble Fibre is a corn based soluble fibre with over twice the digestive tolerance of inulin, reducing the possibility of digestive discomfort. Its high fibre content makes it ideal for use at lower inclusion levels to reach nutritional targets.

Abigail Storms, Tate & Lyle’s SVP fibre and sweetener platform, said: “Our customers appreciate Tate & Lyle has an industry leading soluble fibre production network with capacity in three continents. The addition of this new capacity at this production facility means we can offer customers even greater security of fibre supply at greater speed, supporting consumer demand for more accessible fibre enhanced nutrition.”

Related content

Source: foodanddrinktechnology.com