Teknomek introduces foreign body control box to enhance audit-readiness

Teknomek has introduced its Foreign Body Control Box to its product range for the food processing sector in response to BRCGS Food Safety Standard Issue 9.

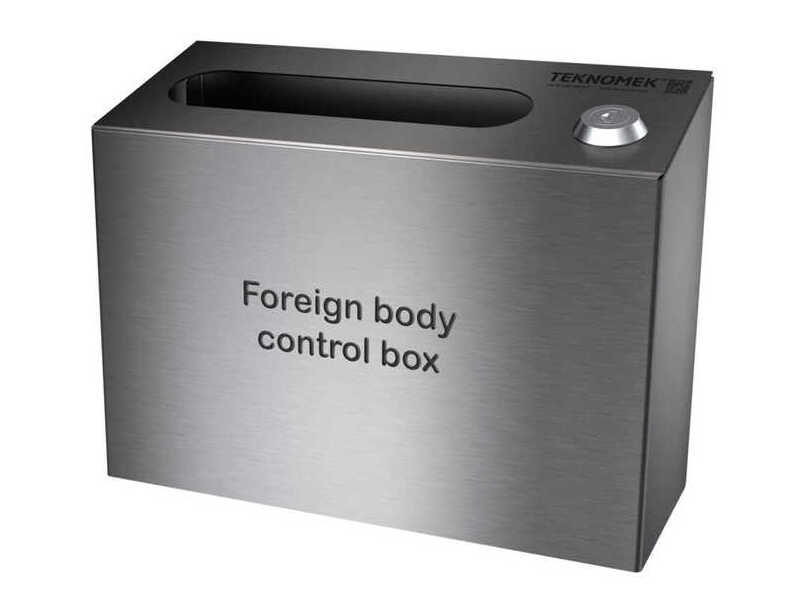

The hygienic furniture specialist said it designed and manufactured the 304-grade stainless steel box to provide food processing companies with a process solution for controlling the risks of foreign body contamination.

The box, which measures 252mm w x 96mm d x 186mm h, provides a central receptacle where any foreign bodies discovered within the food production area can be placed. With a removable tray, the contents of the box can be easily removed, investigated, and route cause analysis undertaken to minimise further incidences and prevent further non-conformances.

Michelle Locke, product and marketing manager at Teknomek, notes that by owning non-conformances such as foreign body contamination food production businesses can enhance their hygiene standards and ensure that they are always audit ready.

Locke says: “Having a foreign body control box in plain sight demonstrates to both your staff and any visiting BRCGS auditor that you take potential contamination risks extremely seriously and have a process in place to deal with them.”

The latest version of the BRCGS Food Safety Standard introduced a new clause (4.9.6.3) stating: ‘Based on risk, procedures shall be implemented to minimise other types of foreign-body contamination (ie types of contamination that are not specifically covered in section 4.9). Foreign matter not included in clause 4.9 can include toolbox contents such as spare nuts and bolts, cable ties or even odd items of stationery such as spare printer cartridges or labels.

Locke adds: “We have all seen out of place items on the factory floor, but the new BRCGS standard makes it very clear that there is no place in a food production area for random pieces of equipment which have no specific purpose and no designated storage space.

“We live in an age of unannounced audits, where an unexpected visit from an auditor can lead to interruptions to production and, worst case scenario, the risk of extended technical review. So being ‘audit ready’ every day has to be a key priority for any professional working within the food industry.”

Giving teams the right processes, tools and training to reduce the risk of foreign body contamination is a core part of ensuring that the fundamentals of hygiene and risk management are thoroughly embedded into operational practices. It is only by leaders establishing and promoting these processes that organisations can be sure that an effective hygiene and safety culture runs throughout their business.

The Teknomek Foreign Body Control Box has been designed and manufactured with smooth welds and sloping surfaces, and contents are readily accessible to allow for easy cleaning and maintenance, so that the box does not become a hygiene risk in itself. Once items have been placed inside, they cannot be taken out without unlocking the box and pulling out the removable tray, ensuring processes are rigorously followed.

Related content

Source: foodanddrinktechnology.com