“World’s largest” 3D food printing facility opens in Vienna

The new plant will bring innovative mycoprotein-based foods using the company’s cutting-edge 3D printing technology.

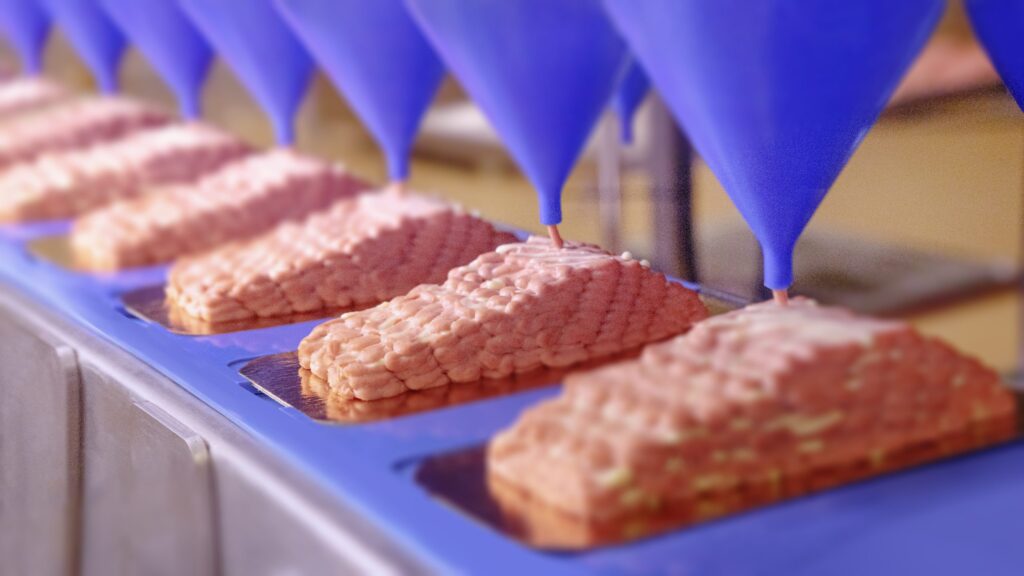

Revo Foods’ flagship product “The Filet”. Credit: Revo Foods

Austrian company Revo Foods has opened the “world’s largest” industrial facility for 3D food printing, known as the Taste Factory. The Vienna plant is set to revolutionise plant-based food production with its proprietary 3D structuring technology, which replicates the textures of meat using mycoprotein – a protein-rich substance derived from fermented mycelium.

Capable of producing up to 60 tonnes of food each month, Revo Foods states the new factory is the world’s first to implement 3D printing on this scale.

The company will debut its first product, “The Filet”, a meat alternative inspired by salmon, in European supermarkets on 3 October. The product is made from mycoprotein and is free from cholesterol, sugar and gluten and is packed with omega-3, vitamins and fibre.

Innovating food manufacturing

CEO Robin Simsa expressed excitement about the launch of the factory, noting its potential to revolutionise the food industry. “With the Taste Factory, we are showcasing that this technology works on an industrial scale.”

Simsa added, “This enables a new generation of food innovations. With 3D Structuring, we can create entirely new textures using simple but nutrient-rich ingredients like mycelium, creating products that are just so much more exciting. “

The innovative process blends materials such as fat and protein to mimic the texture and tenderness of meat products, including plant-based fillets and steaks. Unlike traditional food manufacturing, which often involves high temperatures that degrade nutrients, 3D printing process operates at lower temperatures, preserving vital micronutrients that would otherwise have been lost.

The introduction of 3D Structuring could have significant implications for food manufacturing as it allows for rapid product iteration and customisation, enabling a wide variety of food options to be created more efficiently.

The company is already working with partners to co-develop new products, with the first expected to launch in 2025. Revo Foods is also exploring the potential of personalised nutrition, which could lead to customised food solutions tailored to individual dietary requirements, further expanding its impact on the food industry.

Head of food tech Niccolo Galizzi commented, “Biomasses like fermented mycelium are trending because their natural consistency requires little processing, and they are very nutrient-dense. However, in its pure form, it often tastes bland. We believe that for real change, sustainability and culinary pleasure must go hand in hand.”

Source: newfoodmagazine.com