Don’t be complacent around grain storage hazards

There is a plethora of hazards associated with storing and moving grain. Robert Gobeil, agricultural health and safety specialist for the Canadian Agricultural Safety Association, detailed overarching dangers and how to prevent them at a recent virtual event hosted by Canada’s Outdoor Farm Show.

Hazards

Those entering a storage area containing a grain mass can be sucked under flowing grain, trapped by avalanching grain, as well as fall through crusted or bridged grain (when gaps occur under crusting). Poorer quality grain can exacerbate the potential for these issues. Once within the grain mass, the pressure exerted against the body makes movement impossible.

Why it matters: Injuries and fatalities related to grain storage and movement occur every year. Knowledge of hazards, potential hazards, as well as safety and emergency response procedures are critical to prevention.

The surrounding environment itself (trucks, ladders, building materials, storage spaces, etc.) has a number of hazards.

Bins unstable due to irregular weight distribution can collapse (e.g. is wet grain adheres to one side of the structure). Augers and other machinery used for moving grain can entangle limbs and tools. Gasses from decomposing material and dust can cause harm, and in the case of the latter, even explode given the elements required for combustion are present – specifically, an ignition source, oxygen, and dispersed fuel within a restricted space.

“These spaces are easy to get into, but not get out of,” says Gobeil. “They’re not a place you want to sit and have your lunch.”

People are hazards too. Individuals who are poorly trained or otherwise not knowledgeable about the hazards associated with grain storage, as well as proper precautions and what to do if an incident occurs, can cause problems for themselves and others. The same also applies to those who simply assume someone knows what they are doing.

As the amount of on-farm grain storage, the size of bins, and speed of grain movement continues to increase, Gobeil says these any other hazards associated with grain handling loom ever larger across the agricultural landscape.

Precautions to take

The first step towards preventing injury or death is being aware of what hazards are present – and taking them seriously. A variety of practical steps follow.

Keeping operational controls accessible outside of a grain bin allows individuals to stop machinery should an incident occur. Doing so when a person is sinking into flowing grain, for example, stops the sinking and allows time for appropriate action to be taken.

Electrical systems (e.g. fuse boxes and power controls) should always be locked to prevent power from being turned on while someone is working on a machine or within a storage space. Similarly, appropriate guards and barriers to moving parts must always be replaced after removal for replacement or servicing.

Critical to such situations is a second person – specifically someone to monitor and keep communication open with an individual working within the storage area. Gobeil says the second individual should never enter the bin, but take exterior actions, including shutting down machinery, turning on exhaust or aeration fans, and notifying first responders. Indeed, he reiterates trained first responders should always be the ones performing a rescue.

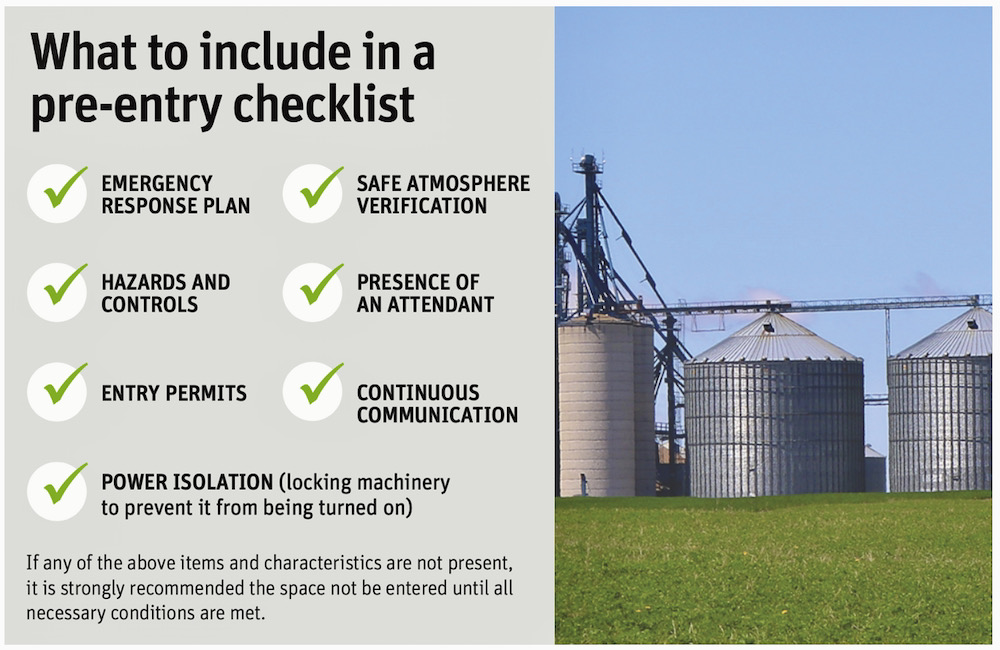

Ensuring all present are properly trained and aware of what they are supposed to do, as well as establishing a pre-entry checklist, is critical. Establishing an assembly point and someone to direct emergency traffic as it arrives on-site is also beneficial. Whether dust masks, harnesses or other materials, the right kind of personal protective equipment must be available – and must be used by all appropriate parties.

“It’s one thing to have these procedures in a binder somewhere, but it’s another thing altogether having your workforce trained in these procedures and knowing what to do and how to respond if an emergency occurs,” says Gobeil, reiterating that taking time to asses rather than rush into a situation is also vital.

Through all grain harvest, movement, and storage activity, Gobeil says four things must be kept in mind:

- Serious incidents often happen when someone is working alone.

- Incidents can involve both grain entrapment and mechanical entanglement.

- When another person is present multiple casualties is possible.

- Would be rescuers can place themselves, others, and victims at greater risk.

Source: Farmtario.com