Labour shortage a challenge for hog barn construction

The shortage of specialized hog barn contractors and a shortage of labour for those contractors could create challenges as Ontario’s swine sector works its way toward compliance with planned loose-housing requirements for sows.

So far, these factors haven’t slowed a boom in hog barn construction, a trend that could continue at least in the short term as costs for building supplies ease into a more affordable range following 2020’s COVID-related supply chain upheaval.

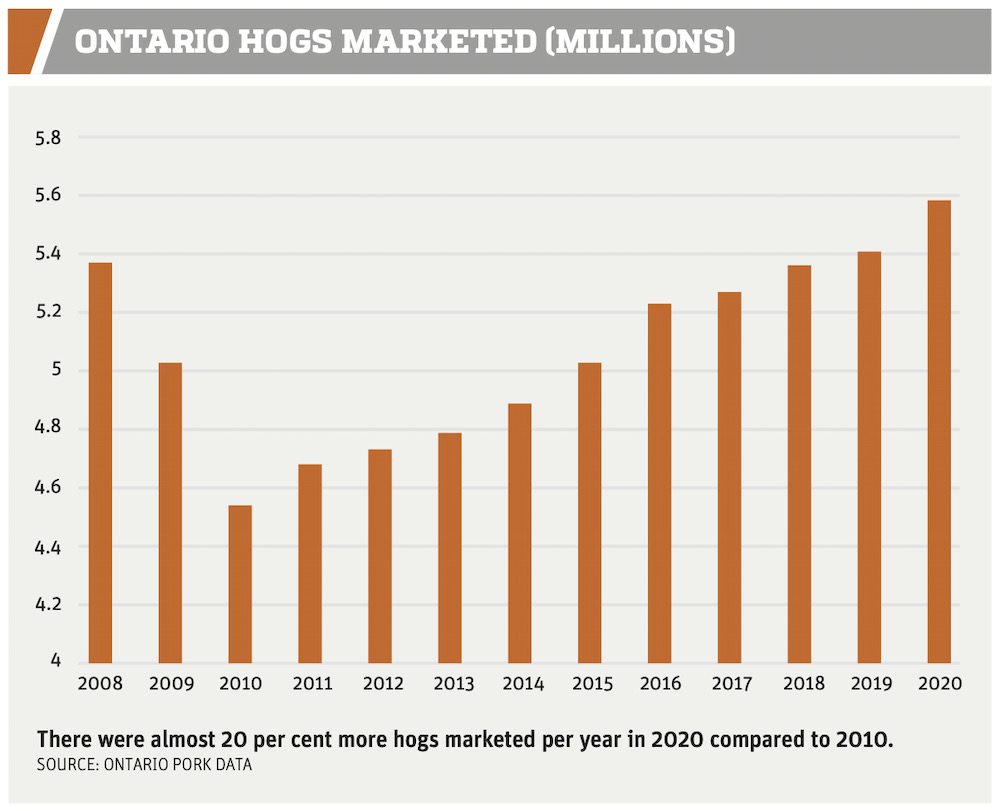

Why it matters: Producers see signs of a rebounding market for pork but facility size limitations may prevent some from taking advantage of that demand.

At Schotman Farms near Alvinston, capacity growth and converting to loose sow housing have been areas of focus for the past few years.

In 2019, Sebringville-area contractor FGC Ltd. built an addition at the farm to introduce loose housing. This year FGC is back on site to create a similar-sized addition that will bring the total length of the barn to 810 feet. That includes 128 farrowing crates and a nursery/holding room.

The farrowing area will be equipped with innovative balance floors from Nooyen, which open a 10-inch height difference between piglets and sows whenever the sow stands up. This prevents the piglets from walking underneath the sow where they can be crushed.

“Once she lays down, the floor will lower and become flush again with the floors that the piglets are on, which allows them to drink from the sow,” Patrick Schotman said.

By freeing space in other parts of the facility, the Schotmans can increase their sow herd from 2,000 to 2,500.

A representative of the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA) said “much of the swine building construction in Ontario is for nursery and finishing facilities, which are not affected by loose sow housing requirements.

“While the reasons for construction are unique to each farm, we expect that sow barn construction is being driven by updates to older buildings and sow herd expansion,” said OMAFRA Media Relations Strategist Christa Roettele.

The new builds or expansions, like the Schotman’s, might not directly create loose sow housing, but indirectly they update other parts of the barn so there is space for that if needed.

The pig code of practice deadline of 2024 for a move to industry-wide loose sow housing for gestating sows was recently extended to 2029 to allow more time for a generational rebuild of sow housing in the province.

“Loose housing required more square footage to house the same number of animals,” said Schotman.

“We, therefore, had to decide to either reduce the size of our sow herd to accommodate loose housing in the building that we had at the time or add on to the barn in order to maintain the size of our sow herd.”

This year’s project had partly the same justification and added enough room for growth. “If we were going to be putting on an addition, we might as well go bigger than was necessary to allow us to expand our herd.”

Schotman sees benefits in a step-by-step movement into loose sow housing.

“The two years since (the 2019 expansion) has allowed us to ensure an easy transition for the sows and ensuring that the health of the herd was maintained. Now that the sows are comfortable with the loose housing set-up, we require more farrowing rooms to accommodate the additional sows.”

Ontario Pork Communications Manager Stacey Ash says a combination of factors, including loose housing requirements, are contributing to the building boom.

“Hog barns have a limited life span so new builds may be replacing older infrastructure,” she said. New housing requirements and changing consumer expectations are also factors.

Ontario Pork doesn’t track individual on-farm construction projects.

photo:

darcymaulsby/iStock/Getty Images

Schotman says he’s thankful this year’s project was planned in conjunction with the earlier addition. Because of that, he had no difficulty securing a contractor or getting work scheduled.

He knows everyone isn’t so lucky.

“There has definitely been a boom in hog barn construction this year in Ontario,” said Schotman, who is hoping to move sows into the new addition at the end of October.

Roettele agreed those hoping to quickly plan and build a barn or expansion will likely be disappointed.

“With very few contractors in Ontario specializing in swine barn construction, most projects are forecasted months and years in advance.”

FGC is widely recognized as a leader in hog barn construction and innovation – so much so that another farm building contractor interviewed by Farmtario described company founder Fred Groenestege as “the king of pig barns in Ontario.”

Groenestege declined an interview, saying his company is too busy.

As well, a severe shortage of labour is what he referred to as a crisis in the farm building sector.

Ash agreed.

“In general, hog farmers planning new construction or renovations since the onset of the COVID-19 pandemic face challenges similar to those experienced by other sectors, including labour shortages and increased supply costs,” she said.

“With construction trades in high demand, and many producers still recovering from financial challenges related to COVID-19 market disruptions, some projects may be delayed.”

Source: Farmtario.com