Food safety is based on the correct handling, production, distribution and storage of food and raw materials, in order to avoid physical, chemical and microbiological contamination. We talked about this with Marzia Arborea of Agro.Biolab Laboratory, one of the most qualified laboratories in Italy.

Agro.Biolab Laboratory’s headquarters

Agro.Biolab Laboratory’s headquarters

Food safety issues have become increasingly important over time, partly because some raw materials and products are imported from countries where food legislation may be less restrictive than in Europe. Among the possible contaminations found on food, a large number of irregularities are due to microbiological contaminations, as documented by the Rapid Alert System for Food and Feed (RASFF) which has detected as many as 928 contaminations by pathogenic microorganisms (Salmonella spp and Listeria monocytogenes) out of a total of 1,145 Alert Notifications during 2019″.

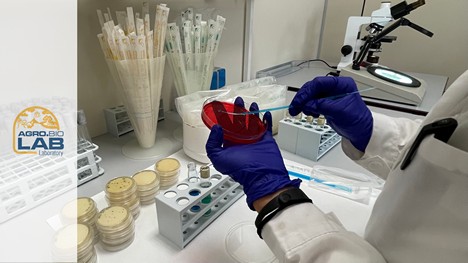

A phase of the test to detect Salmonella spp. in a food matrix

A phase of the test to detect Salmonella spp. in a food matrix

But what are the foods most at risk, at least for the fruit and vegetable sector, and how can the risk be contained?

“Dried fruits, seeds, vegetables, dietary foods and supplements are among the product categories most notified by the RASFF. In order to reduce the risks of microbiological contamination, we need to increase the level of knowledge regarding the mechanisms of transfer, survival and growth of microorganisms in agri-food products, in order to implement a proper risk assessment and an effective control system aimed at protecting consumers’ health. The origin of microbial contamination of plant foods is often difficult to identify. The origin of microbial contamination of fresh fruit and vegetables is mainly due to irrigation water and soil, particularly if it is enriched with manure. For processed vegetables, contamination is frequently linked to the improper sanitation of food processing and storage equipment and surfaces, as well as to the contact of workers handling food at various stages of the supply chain,” explained Arborea.

“In order to reduce the risk of contamination, it is advisable to plan and carry out structured microbiological monitoring at different stages of production and on different matrixes. This starts with the raw materials, continues during the various processing stages and ends with the finished product, in order to monitor the production system and identify critical points where potential contamination may occur. Another key point is the control of the water used for processing, treatment and storage of the product, to assess its potability (Legislative Decree 31/2001). Another important aspect is the analysis of swabs from worktops and tools so as to ensure the efficiency of surface washing and disinfection systems. Equally important are the swabs of gloves and other supports worn by the operators, to check that the hygiene practices established by the company are respected.”

Preparation of a sample for microbiological analysis

Preparation of a sample for microbiological analysis

In compliance with the criteria of process hygiene and food safety (Annex 1 of Regulation 2073/2005), Agro.Biolab Laboratory is able to select indicator bacteria and to detect pathogenic microorganisms that may represent a risk in the production process. The tests are accredited to ISO 17025 and include a wide variety of in-house and official methods (ISO, AFNOR, APAT, etc). The activities of the microbiology department include more complex investigations, such as stability and shelf-life analyses.

The modern laboratory meets the most rigorous quality standards and offers services that can be tailored to individual needs.

For more information:

Marzia Arborea

Agro.Biolab Laboratory srl

commerciale@agrobiolabitalia.it

www.agrobiolabitalia.it