SIG removes the need for third-party pre-sterilisation of spouted pouches

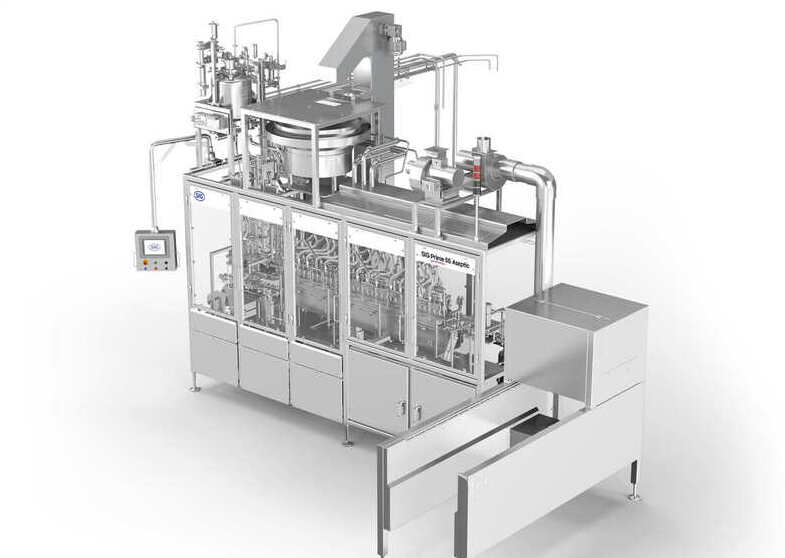

SIG has launched a new aseptic spouted pouch filling system, the SIG Prime 55 In-Line Aseptic filling equipment for pre-made spouted pouch features in-line pouch sterilisation, removing the need for third-party pre-sterilisation of spouted pouches.

The resulting system reduces supply chain complexity and improves the overall costs to produce aseptically packaged products in spouted pouches.

The new filling system has reached commercialisation and was featured in conversations at the 2024 Anuga FoodTec exhibition in Cologne, Germany.

Christoph Wegener, chief markets officer at SIG, celebrated the system release when he noted SIG’s considerable history in the development of technology for aseptic packaging.

He continued: “This new filling system offers technological progress by transferring SIG’s expertise in aseptic filling technology with in-line sterilisation, which has been successfully in use for decades in the field of carton packs, to spouted pouches. The breakthrough here is a new and unique way of sterilising spouted pouches in-line, ensuring sterilant flow and coverage of the packaging while it’s in the filling tunnel. By eliminating the need for pre-sterilisation of the pouches, we’re able to give producers full control and flexibility of their production. This is an exciting time for SIG and an important step forward in our journey to enable brands to produce more nutritious foods for better We are extremely proud that we will soon be trialling the system with recycle-ready SIG pouches. They will be a world first in our industry.”

Aseptically packaged food and beverages retain their high quality and can be stored for a long period without refrigeration or preservatives. Resulting products like fruit puree, sauces, and baby food taste great and maintain nutritional value, explained Massimo Annaratone, global business line director of spouted pouch at SIG.

“With the SIG Prime 55 In-Line Aseptic, we have further advanced the potential reach of better nutrition through a system that combines quality, SIG-produced spouted pouches with proven in-line sterilisation technology delivering >log 5 reduction in production,” he said. “The conversion from retorted and hot-filled products in cans, plastic bottles, and glass to convenient aseptic spouted pouches has never been more compelling.”

Related content

Source: foodanddrinktechnology.com