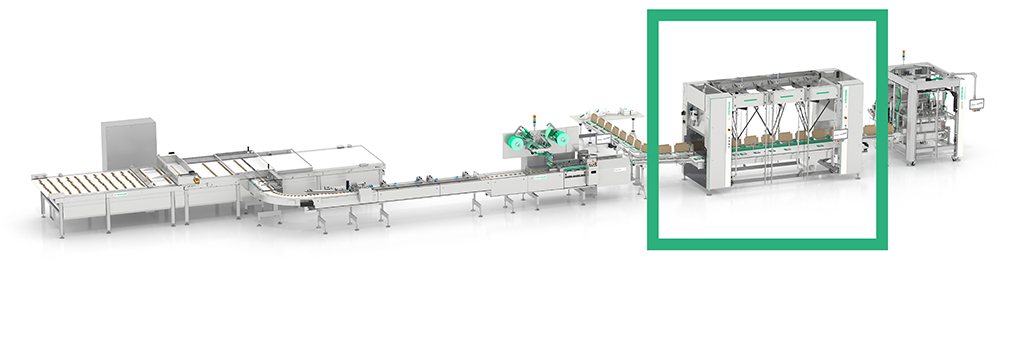

Syntegon launches new pick-and-place platform

The Covid-19 pandemic has further fuelled the automation megatrend. Manufacturers of different products, especially food, increasingly rely on robotic solutions to automate critical process steps or to fully automate entire systems. Syntegon Technology has been offering robotic solutions for process and packaging technology for many years. With its newly developed robotic pick-and-place platform, Syntegon RPP, the company is setting a new standard in the automation of packaging lines.

“We are more than ready for the requirements for the factory of the future. Automation and robotics are important strategic focus areas for Syntegon,” says Dr Silke Blumer, vice president, Strategy and Product Management for the business unit Food at Syntegon.

The core functions of the newly developed RPP platform include quality assurance, user-friendliness and efficient production processes. “Thanks to our proven expertise in robotics combined with industrial know-how, we can offer our customers automated turnkey solutions from a single source,” Blumer confirms. “We understand the food industry’s requirements for machines and lines better than any other manufacturer – from process technology to primary, secondary and transport packaging.”

The Syntegon RPP platform automates process steps such as handling, feeding and loading. The new robotics platform is designed as a modular system. This allows individual configuration of the robotic cells. “Each customer project is different. Thanks to the modular RPP platform, we can handle a wide variety of products. The Delta robots can be flexibly connected and, together with transport modules, seamlessly integrated into an overall system,” explains Andreas Schildknecht, product manager Robotics at Syntegon. “Together with our customers, we can automate single process steps consecutively and in line with their needs or budgets, following the principle ‘build as you grow.’ Moreover, the platform can be scaled to suit different production capacities, while multiple cells can be connected.”

The open control software ensures the seamless integration of the Delta robots into the line. “The comprehensive integration of controls and hardware is essential for all components within the line to communicate with each other through a single control platform – and to function perfectly together,” says Schildknecht. The platform, which was designed according to the latest UX aspects, ensures user-friendly operation. New features support the operators in making their daily work with the line easy and effective. The RPP cells provide excellent visibility, easy access and efficient cleaning. The stainless steel robotic cells meet the IP65 protection class. This minimizes the risk of contamination for both current and future hygiene requirements in the food industry. Lastly, the tool-free format changeover reduces downtime, allowing manufacturers to process different products on the same line and to respond quickly to changing market demands.

Related content

Source: foodanddrinktechnology.com